Conversion of an LED strip power supply from an old TV to a WiFi-controlled LED strip

.

.

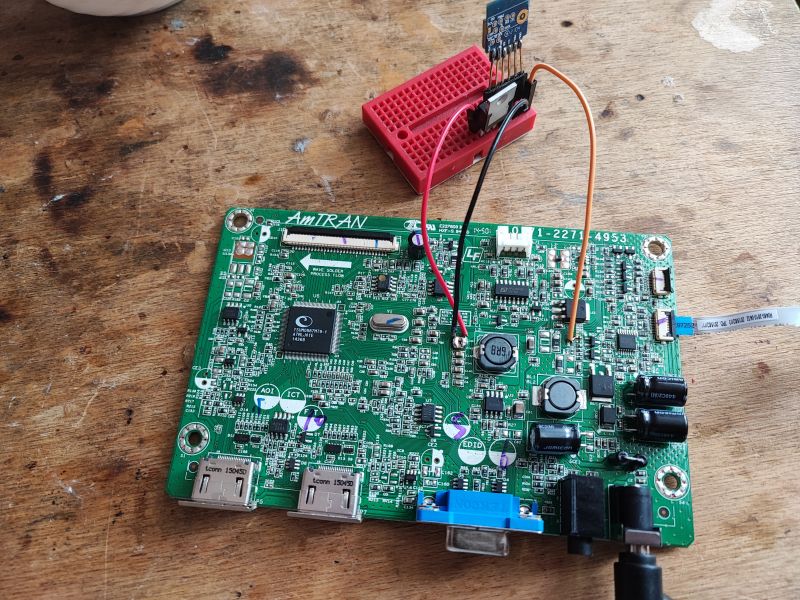

In a previous topic I showed the inside of an Acer S236HL LCD monitor along with its LED backlight. Here I will convert the remnants of this monitor into a WiFi controlled LED strip. For this I will use a WiFi module with a chip similar to the ESP8266 (BK7231). My chip will allow me to control the brightness of the strip and turn it on and off. By using OpenBeken, the whole thing will also be compatible with Home Assistant, allowing this strip to be controlled from any other supported switch and grouped together with other LED strips.

Previous topic: Acer S236HL LCD monitor - interior, design, potential use of LEDs .

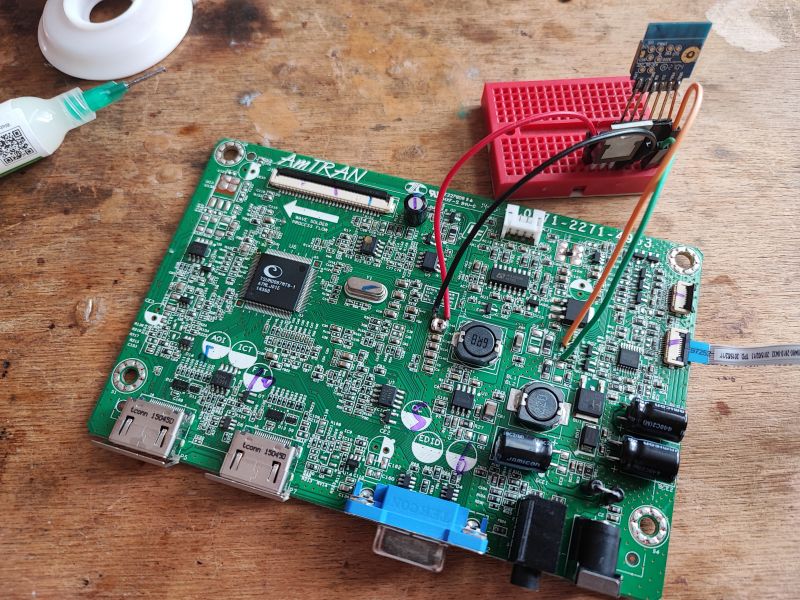

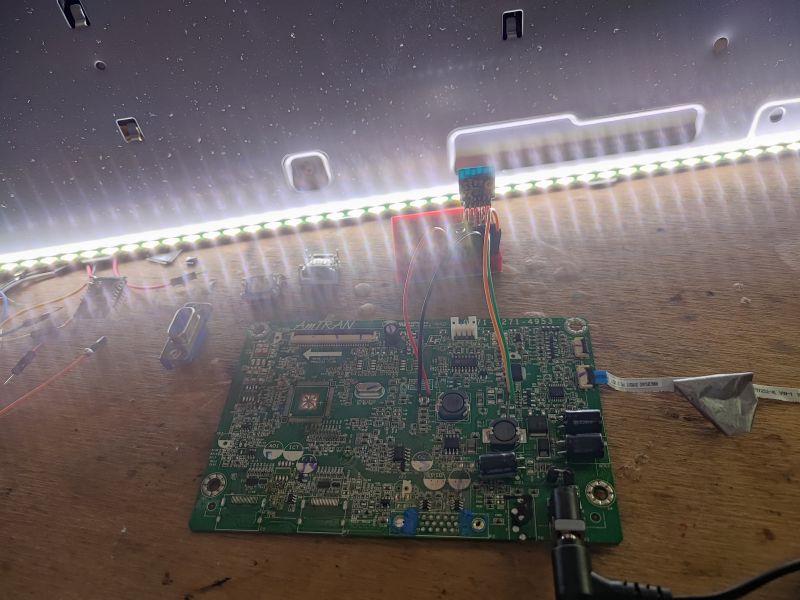

So back to the board:

.

.

The board connected loosely to the backlight and power supply (no buttons, LVDS, etc) still lights up the backlight.

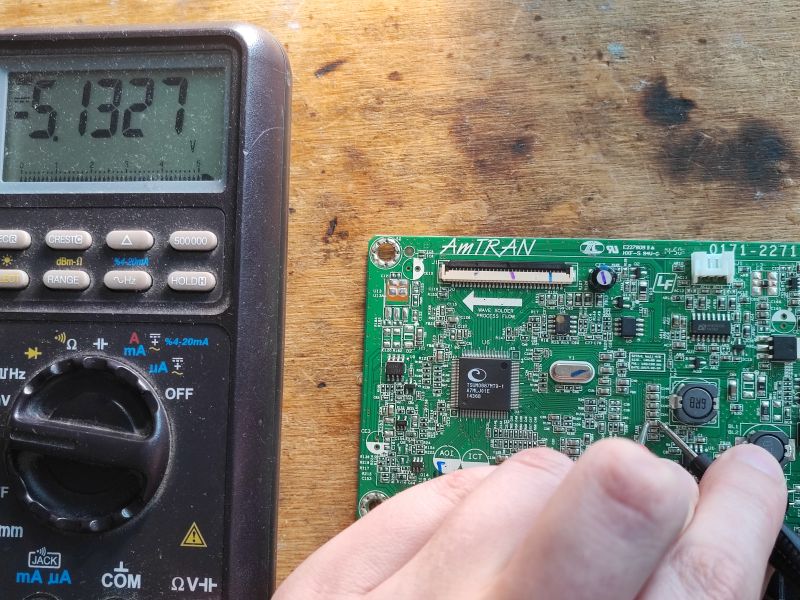

To start with I checked what the voltages were on the board. I found 3.3V, but had doubts about its current capacity. The WiFi module sometimes needs more than 100mA at 3.3V. In the end I decided to use the 5V line but together with the 3.3V LDO:

.

.

So the power supply we have.

Now how to control the LEDs?

.

.

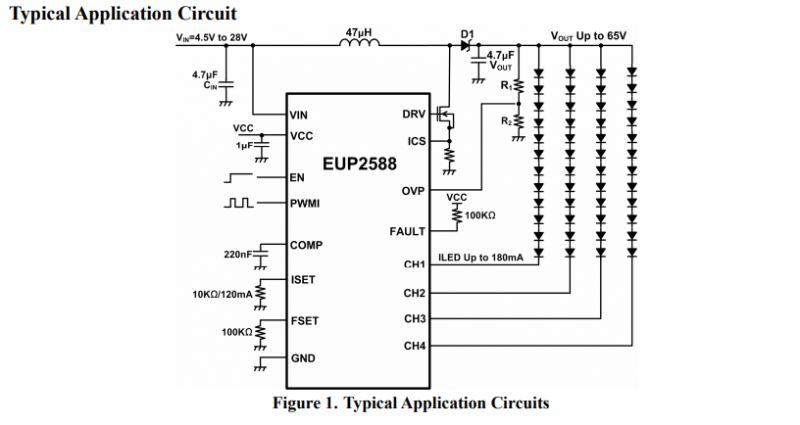

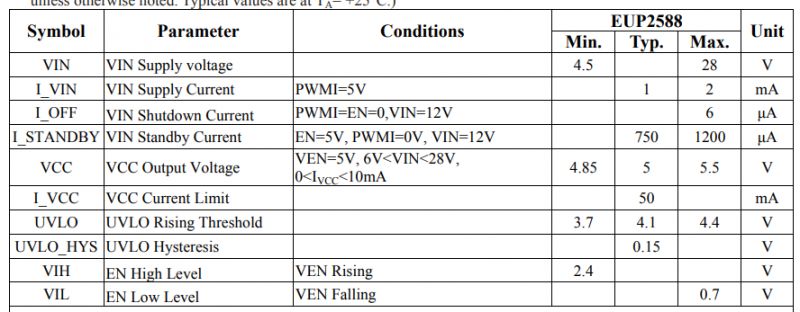

EUP2588:

.

.

We need the EN (enable) and PWM (brightness control) signals.

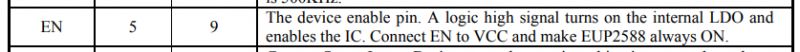

EN requires a high state to enable:

.

.

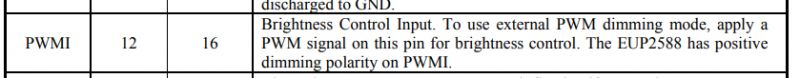

And PWM:

.

.

Only question now, how is this connected to the main controller?

Need to see if this can be driven from the MCU:

.

.

The high level is from 2.4V, so an MCU running at 3.3V will be able to drive this.

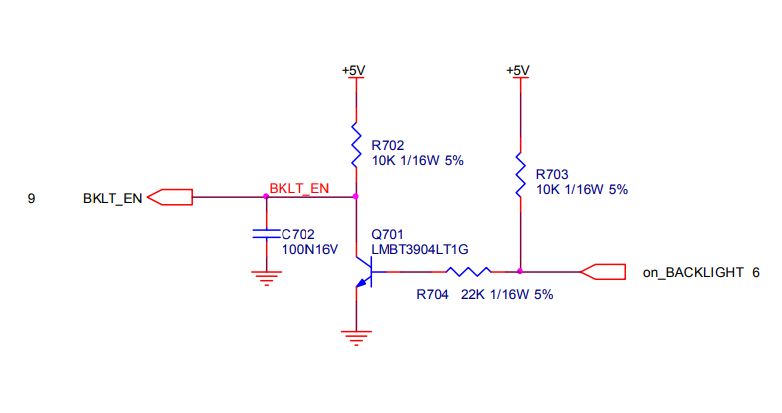

I also looked for a schematic. This particular board was not available, but I looked at similar schematics:

.

.

I was a bit surprised that there is a pull-up here with a transistor, now a high state on the base of this transistor will result in a low state on BKLT_EN.... but this can be corrected in the firmware.

This starts with the power supply:

.

.

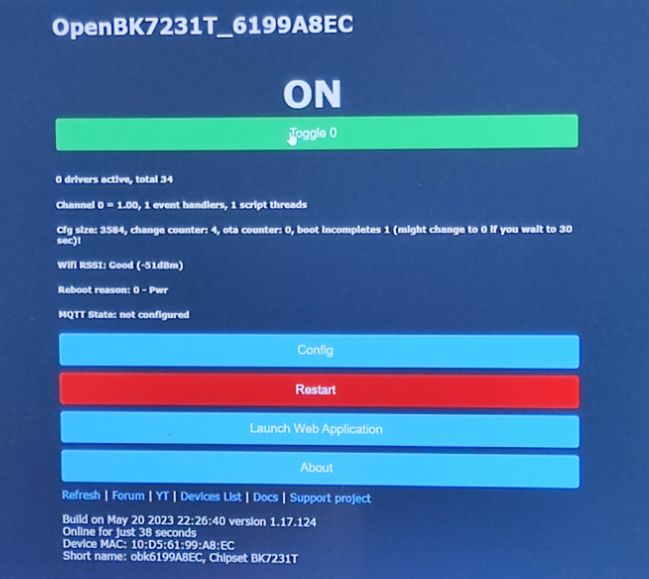

The WiFi module has checked into the network, it works.

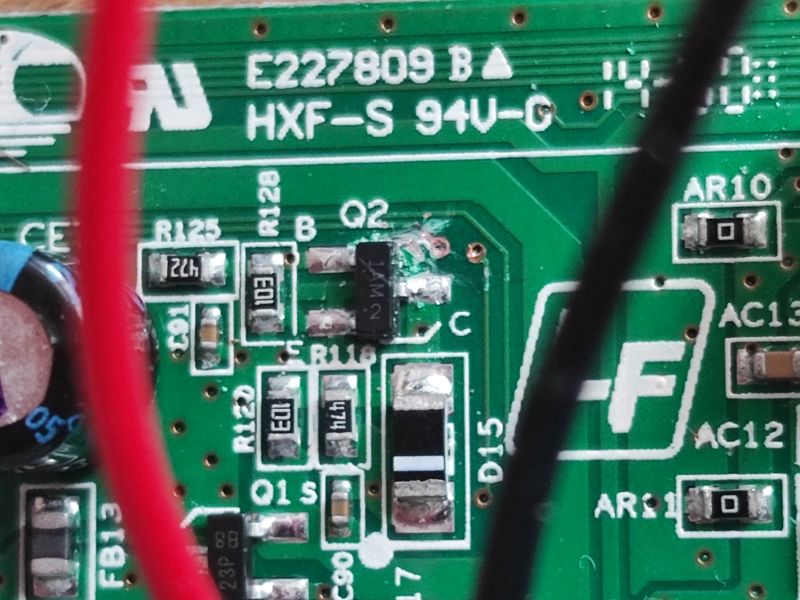

Now EN and PWM - I examined the paths and came to the conclusion that, as in the schematic attached above, the main MCU here controls them via transistors. In addition, they do indeed have pull-up resistors.

So I cut the path:

.

.

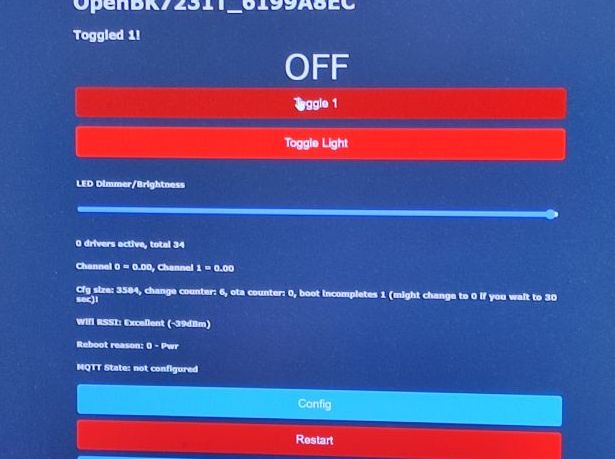

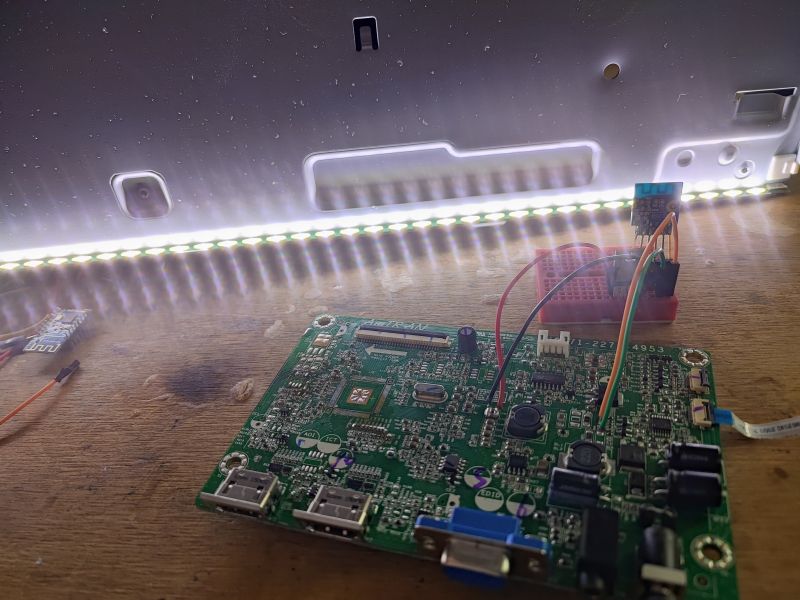

On/Off works:

.

.

LEDs can be controlled.

I have connected the PWM similarly:

.

.

In the OBK I enabled the PWM (the two buttons are a side effect of the PWM and Enable pins separately):

.

.

Finally, I gradually soldered the unnecessary components off the PCB:

.

.

I had concerns that the main processor was controlling something else, that maybe there was a transistor along the way and that I would have to short or switch it, but no. The isolated LED chip continues to work.

The video doesn't show the effect very well, as the camera adjusts to the brightness of the strip and you can't see the dimming very well....

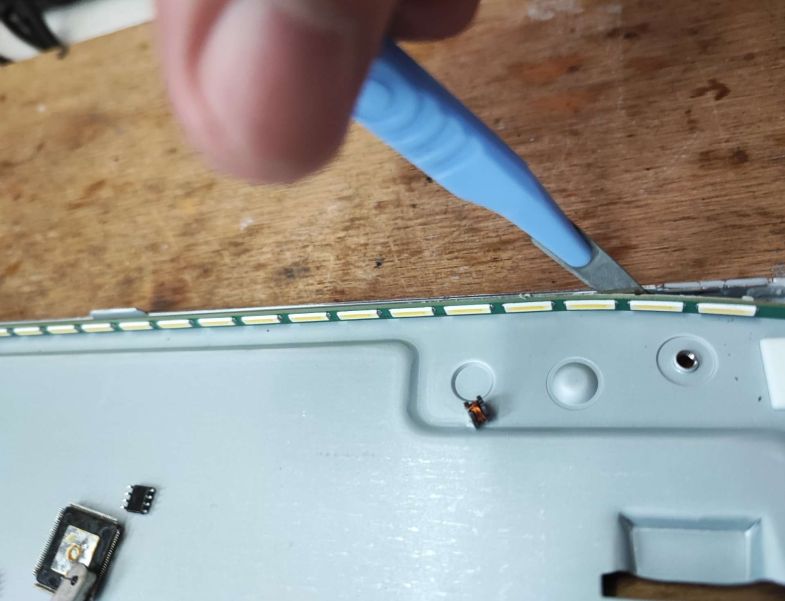

What remains is to free the LED strip from the housing. It is glued to it with a special double-sided tape. All you have to do is lever it up with a thin knife:

.

.

This way you get a freed LED strip:

.

.

Only now note - the belt in this form is not able to dissipate heat effectively and will damage itself quickly! Now you need to find some way to cool it properly, maybe stick it on some angle iron etc.

In addition, I have added a script in the OBK for improvement purposes:

again:

setChannel 2 $led_enableAll

delay_s 0.1

goto again

This script automatically exposes the LED controller state to the second channel.

Summary .

This time there were no major problems. Basically, it turned out that the entire LED module is controlled by just two signals - Enable and PWM - which are easily produced on an external MCU. Additionally, there was already a step-down inverter on board the board providing 5V, so there was no problem with the external power supply only giving 19V.

On the firmware side it also went smoothly, I only had to add a small script to control the EN pin, and to because practically all LED strips on sale do not have an EN pin, and only the PWM alone controls them, and here there is a separate EN and a separate PWM.

Basically the project is successful, now I just need to find a rail for these LEDs (to dissipate heat) and then mount them somewhere. By the way, do you have any suggestions on how to implement this? What to glue them with? Perhaps in the third part, I will show the implementation of this, also with some kind of mounting or housing for the controller (I will add an encoder so that it can also be controlled without WiFi).

Comments