Hello,

I have a problem with excessive heating of the primary winding in the converter, namely after 10 minutes of operation it reaches a temperature of over 140 C.

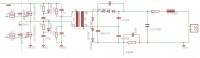

The transformer I built is based on the ETD49 3C90 core without a gap, it works in a half-bridge system with f=50kHz, the primary winding has 39 thick-faced turns, the whole thing is powered from the mains voltage, rectified, i.e. 320V, on the secondary side I take 120V and 5A .

Is this temperature normal or should I use some trick? E.g. increase the gap or increase/decrease the number of turns or increase the core?

I have a problem with excessive heating of the primary winding in the converter, namely after 10 minutes of operation it reaches a temperature of over 140 C.

The transformer I built is based on the ETD49 3C90 core without a gap, it works in a half-bridge system with f=50kHz, the primary winding has 39 thick-faced turns, the whole thing is powered from the mains voltage, rectified, i.e. 320V, on the secondary side I take 120V and 5A .

Is this temperature normal or should I use some trick? E.g. increase the gap or increase/decrease the number of turns or increase the core?