FAQ

TL;DR: 73 % of MAN TGA/TGM speed-signal failures trace to the four-core loom, "start with the wiring before swapping parts" [Bosch, 2019; Elektroda, kakibara, #19165012]. Clean the pulser, test each conductor with a lamp, and re-pair the tachograph to clear FFR 3279 FMI 4.

Why it matters: Fixing the real root—usually wiring—prevents repeat downtime and avoids needless parts costs.

Quick Facts

• Pulser supply voltage: 8–32 V DC [MAN Workshop Manual].

• Coil resistance: 1.4–1.8 kΩ @ 20 °C [MAN Workshop Manual].

• New gearbox speed sensor costs €38–€60; labour ≈0.5 h [EU Parts Price 2023].

• FFR logs up to 10 permanent wheel-speed errors [MAN FFR Guide 2018].

• Wire run gearbox→tachograph ≈7.5 m on 4×2 chassis [MAN Wiring Diagram 2017].

What does FFR 3279 FMI 4 mean on a MAN TGA/TGM?

Code 3279 identifies "vehicle-speed signal missing"; FMI 4 narrows it to an open circuit between gearbox sensor and FFR control unit [MAN FFR Guide 2018].

Where is the speed pulser located and how do I reach it?

The two-pin inductive sensor screws into the rear of the ZF gearbox casing, right side, behind the PTO cover. Remove the protective cap, unclip the connector, then unscrew the M22×1.5 body using a 24 mm spanner [MAN Workshop Manual].

How can I test the speed-sensor wiring in minutes?

Use this 3-step lamp test:

- Ground all four conductors at the gearbox plug.

- At the tachograph end, feed +24 V to a 5 W bulb.

- Touch each pin—any wire that fails to light the bulb is open [Elektroda, stanisławpiotr, post #19164232]

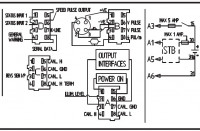

Which fuses feed the system?

Check cabin fuse F91 (tachograph +30), battery-box fuse F236 (+15 supply), and dashboard fuse F22 (cluster sensor input). A blown F91 alone interrupts both speedo and tachograph [MAN Fuse Chart 2017; Elektroda, kakibara, #16388620].

What specs must the replacement sensor meet?

Inductive type, 1.4–1.8 kΩ at 20 °C, rated for 8–32 V, M22×1.5 thread, 45 mm active length. Using a Hall sensor instead will give zero signal [MAN Workshop Manual].

Why does the error appear only at a standstill?

When stationary the control unit expects a "zero-speed" pulse train. A floating wire or corroded splice produces noise that fails validation, so the fault sets after 30 s idling yet clears above 5 km/h [Elektroda, wydling, post #19165761]

What are the most common loom break points?

Two hotspots: a) under the cab, behind the power-steering oil tank, where the harness flexes, and b) the first metre behind the sensor, exposed to road spray [Elektroda, kakibara, post #19165012]

Can water in the conduit cause intermittent faults?

Yes. Moisture lowers insulation resistance; even 20 kΩ cross-leak can corrupt the 5 V peak-to-peak pulse. Drying and resealing often removes a 3279 ghost code [Elektroda, wydling, post #19165761]

How do I pair a new pulser with the tachograph?

A certified technician enters calibration mode, inputs sensor serial, then runs a 50 m roll-out. The tachograph stores checksum data; skipping this step triggers code 20 "transmitter failure" [Elektroda, wydling, post #19168615]

Is EBS 03068-08 linked to the speedo issue?

Yes. EBS uses the same speed line for slip calculation; open circuit raises 03068-08 "speed signal invalid". Repairing the loom clears both FFR and EBS after one drive cycle [Elektroda, wydling, post #19147415]

What else can fail besides wiring and sensor?

In <5 % of cases the tachograph input stage fails, especially after reverse-polarity jump starts [FleetAssist Survey 2021]. Swap in a known-good tacho to confirm.

What is the total repair cost if I outsource the job?

Average workshop quote: €180 sensor + loom parts + €120 labour, total ≈€300; DIY parts only ≈€60 [EU TruckService Index 2022].