Why does SMT Technology Benefit PCB Assembly?

JLCPCB SMT technology allows fabrication yield. Compared with THT or hand soldering, SMT is more suitable for automated production. THT requires different insertion machines (DIP insertion machine, radial insertion machine, axial insertion machine, tape machine, etc.) According to different components, each machine needs to adjust the assembly time, and the maintenance workload is large. SMT can install all types of SMC/SMD by using one placement machine with different feeders and pick-and-place pins, which reduces adjustment preparation time and maintenance workload.

Compared with JLCPCB PCB assembly, hand soldering has a high risk of making defective boards. In addition to the solder paste printing machine, pick and placement machine, and reflow oven that needs to attach electronic components to the circuit board, the JLCPCB PCBA service has enough inspection equipment.

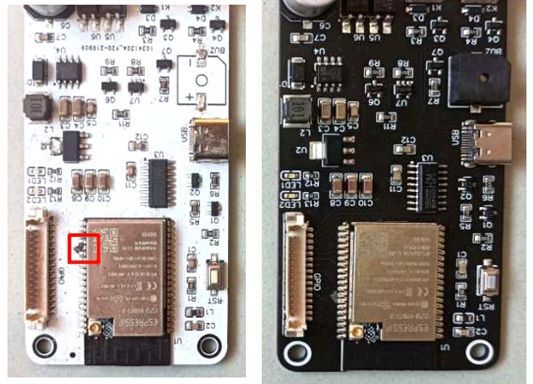

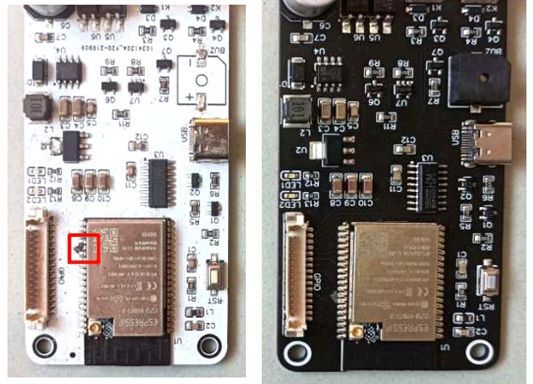

Visible Difference:

• White PCBA: This PCB is hand soldered, using the same components. ESP32 module is shorted due to too much solder between the two pins.

• Black PCBA: It's a PCB soldered using the JLCPCB SMT service, the soldering is done professionally and the components are properly aligned.

Invisible Fault: Detached Pads on the Component’s Bottom Side

The below board is showing PCBs with UVC LEDs assembled. These UVC LEDs have solder pads on the bottom side, like BGA. For the first prototyping, I used JLCPCB’s PCBA service, and the prototype worked well as it was designed.

What are the benefits of the JLCPCB PCB assembly service?

From hundreds of domestic users growing to nearly 100,000 PCBA users globally now, more and more customers choose and benefit from JLCPCB PCB assembly service. JLCPCB is at the forefront of the PCB manufacturing industry, and clearly solves the pain points of this industry and the needs of users. Especially this service can appropriately satisfy new products’ R&D. It really meets our PCB engineers' needs. We can start our own businesses without worries because of JLCPCB. Below are the benefits of JLCPCB PCB assembly service:

1. Cost-effective:

JLCPCB sends every customer the $24 SMT coupon to enjoy PCB assembly service. Authentic components, high equipment, factories, and professional technical teams to achieve engineers' real profits. JLCPCB has insisted on $2 for 5pcs 1-8 Layer PCBs, a Special Offer of $25 for flex PCB, and 3D printing from $1.

JLCPCB components price is transparent: PCB assembly components' price is clearly marked. Compare to the buy-as-you-go mode, pre-order parts allow people to get a favorable price. Pre-order service adopts real-time quotation service, and the price is transparent and open. Customers can purchase on-demand without worrying about the loss of payment due to the failure of the pre-order service.

JLCPCB is able to obtain more low-cost but high-quality parts from reliable global parts suppliers. The bargaining power of JLCPCB can help small and medium-sized enterprises or individual customers reduce cost risks, collect various component needs, and negotiate prices with trusted component suppliers.

2. Large component library:

The JLCPCB assembly parts library provides 350k+ in-stock parts & a million global parts.

JLCPCB has a large selection of components for PCBA orders to achieve 100% parts assembly. In case the parts suddenly run out of stock when PCB assembly is needed, they provide the pre-order parts service based on the JLCPCB assembly parts library. If the JLCPCB parts library still can't fulfill your PCBA order to get all parts assembled on your boards, you can refer to the global sourcing service that sources and stocks parts from JLCPCB and global distributors, like Digikey, Mouser, TI, etc.

Please note the parts pre-order service or global sourcing service is only for PCB assembly orders, the parts won't be shipped separately to you.

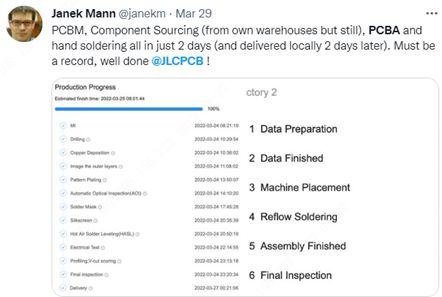

3. Fast turnaround time:

Saving engineers time requires advanced factories and equipment. Self-operated factories are the primary condition to ensure high-efficiency SMT production lines. Self-operated factories can achieve quality control and mass production.

At present, JLCPCB's 6 large self-operated factories have high-end equipment and professional technical teams to ensure stable production of 96 SMT production lines. 90% of SMT orders only take half a day of production: PCB, stencil, and components are produced in self-operated industrial centers, with guaranteed quality and delivery.

In the JLCPCB factories, AGV is used to realize PCB production, no transfer is requested: component preparation, and stencil production until PCBA.

Technology brings high SMT technology, which avoids the harm from hand soldering, and allows engineers to have more energy to benefit human beings and enjoy more fun in life. Batch production can be handed over to JLCPCB. Its standardized independent online ordering method only takes 12 hours for assembly. Once the PCB file is approved, the delivery of PCB+SMT can be completed the next day.

4. Quality assurance:

JLCPCB follows strict quality control measures to ensure that assembled PCBs meet the required standards. They perform visual inspections, automated optical inspections (AOI), and X-ray inspections, among other tests, to maintain high-quality production.

Why is JLCPCB PCB assembly your best choice?

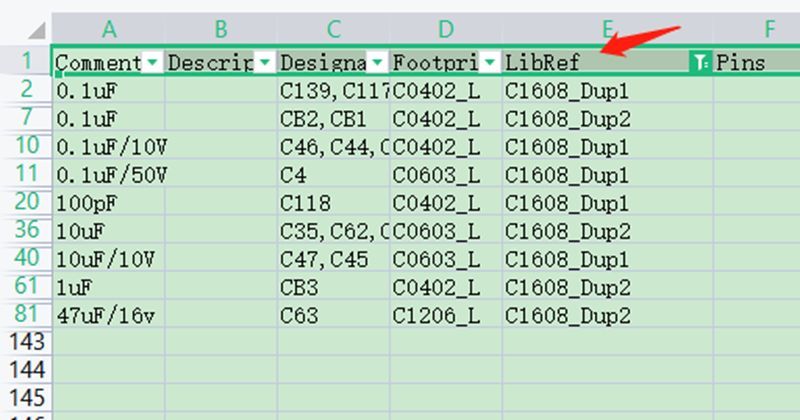

JLCPCB PCB assembly service has always been committed to providing efficient, self-help services. The matching of orders is the highest frequency, and it is also the most critical technology to improve the efficiency of the effect. In 2021, JLCPCB set up a special project team to improve this automatic matching rate. They first created a system to measure whether the matching rate has indeed improved, and at the same time, they can quickly locate the problem of customer matching.

Case:

"We use the monitoring and debugging functions of our system, and we feel strange, according to the stock price, the package should match another C1525, how come it is C1608?"

"It is found that the matching of the diagnosis is the C number matching, and then when the customer contributes the customer number, we query the customer's BOM. The customer's library file is C1608, and we use C1608 first as the store's number."

JLCPCB spent time fixing compatibility issues with messy BOMs. To mine the product number, the success rate has been increased by 5%. It is difficult for technology to be beneficial to everyone, and they only speak with data. After 1 year of development, the auto-matching rate rose from 54% to 85%. Only 15% of parts need to be chosen by yourself when ordering PCBA on JLCPCB. Customers and salesmen have always been praised, and this matching rate also allows us to actively monitor problems.

SMT matching is still iterating, and JLCPCB will gradually improve it. It is estimated that JLCPCB SMT matching will increase by more than 6% points by the end of this month, which is estimated to be the highest level of matching rate in this industry.

JLCPCB - Engineers' best PCBA choice

Keeping an open mind and embracing every customer is the working attitude of JLCPCB. Customer opinions and feedback are the motors of the JLCPCB SMT project progress. Listening and communicating go both ways. JLCPCB serves 172 countries around the world, serving 1,000,000 +Customers, with higher than 99.97% On-time delivery, and lower than 0.23% Quality Complaint Rate. Remarks from PCBA customers:

JLCPCB has been committed to reducing PCB/PCBA costs, improving the ordering experience, and speeding up lead time and shipping. Many entrepreneur customers said JLCPCB helps them to improve their business through time and cost-saving.

"Besides PCB assembly, we like JLCPCB free gifts, packages, and people!"

"Open the box on the top side. We have cardboard, some bubble wrap, another layer of bubble wrap and another roller wrap. You can see PCB wrapped in bubble wrap and not just cardboard has some foam inside and some more power wraps of damage during shipping. It's almost impossible anyway".

In terms of the current performance, we would like to define JLCPCB SMT as a mode. SMT is no longer be a factory, but a connection in the production chain in the future. JLCPCB SMT remembers the original aim and will make every endeavor an extremely great customer experience. Saving your PCB assembly now and in the future, get JLCPCB $24 monthly SMT coupon!

[ADVERTISING COOPERATION]

JLCPCB SMT technology allows fabrication yield. Compared with THT or hand soldering, SMT is more suitable for automated production. THT requires different insertion machines (DIP insertion machine, radial insertion machine, axial insertion machine, tape machine, etc.) According to different components, each machine needs to adjust the assembly time, and the maintenance workload is large. SMT can install all types of SMC/SMD by using one placement machine with different feeders and pick-and-place pins, which reduces adjustment preparation time and maintenance workload.

Compared with JLCPCB PCB assembly, hand soldering has a high risk of making defective boards. In addition to the solder paste printing machine, pick and placement machine, and reflow oven that needs to attach electronic components to the circuit board, the JLCPCB PCBA service has enough inspection equipment.

Visible Difference:

• White PCBA: This PCB is hand soldered, using the same components. ESP32 module is shorted due to too much solder between the two pins.

• Black PCBA: It's a PCB soldered using the JLCPCB SMT service, the soldering is done professionally and the components are properly aligned.

Invisible Fault: Detached Pads on the Component’s Bottom Side

The below board is showing PCBs with UVC LEDs assembled. These UVC LEDs have solder pads on the bottom side, like BGA. For the first prototyping, I used JLCPCB’s PCBA service, and the prototype worked well as it was designed.

What are the benefits of the JLCPCB PCB assembly service?

From hundreds of domestic users growing to nearly 100,000 PCBA users globally now, more and more customers choose and benefit from JLCPCB PCB assembly service. JLCPCB is at the forefront of the PCB manufacturing industry, and clearly solves the pain points of this industry and the needs of users. Especially this service can appropriately satisfy new products’ R&D. It really meets our PCB engineers' needs. We can start our own businesses without worries because of JLCPCB. Below are the benefits of JLCPCB PCB assembly service:

1. Cost-effective:

JLCPCB sends every customer the $24 SMT coupon to enjoy PCB assembly service. Authentic components, high equipment, factories, and professional technical teams to achieve engineers' real profits. JLCPCB has insisted on $2 for 5pcs 1-8 Layer PCBs, a Special Offer of $25 for flex PCB, and 3D printing from $1.

JLCPCB components price is transparent: PCB assembly components' price is clearly marked. Compare to the buy-as-you-go mode, pre-order parts allow people to get a favorable price. Pre-order service adopts real-time quotation service, and the price is transparent and open. Customers can purchase on-demand without worrying about the loss of payment due to the failure of the pre-order service.

JLCPCB is able to obtain more low-cost but high-quality parts from reliable global parts suppliers. The bargaining power of JLCPCB can help small and medium-sized enterprises or individual customers reduce cost risks, collect various component needs, and negotiate prices with trusted component suppliers.

2. Large component library:

The JLCPCB assembly parts library provides 350k+ in-stock parts & a million global parts.

JLCPCB has a large selection of components for PCBA orders to achieve 100% parts assembly. In case the parts suddenly run out of stock when PCB assembly is needed, they provide the pre-order parts service based on the JLCPCB assembly parts library. If the JLCPCB parts library still can't fulfill your PCBA order to get all parts assembled on your boards, you can refer to the global sourcing service that sources and stocks parts from JLCPCB and global distributors, like Digikey, Mouser, TI, etc.

Please note the parts pre-order service or global sourcing service is only for PCB assembly orders, the parts won't be shipped separately to you.

3. Fast turnaround time:

Saving engineers time requires advanced factories and equipment. Self-operated factories are the primary condition to ensure high-efficiency SMT production lines. Self-operated factories can achieve quality control and mass production.

At present, JLCPCB's 6 large self-operated factories have high-end equipment and professional technical teams to ensure stable production of 96 SMT production lines. 90% of SMT orders only take half a day of production: PCB, stencil, and components are produced in self-operated industrial centers, with guaranteed quality and delivery.

In the JLCPCB factories, AGV is used to realize PCB production, no transfer is requested: component preparation, and stencil production until PCBA.

Technology brings high SMT technology, which avoids the harm from hand soldering, and allows engineers to have more energy to benefit human beings and enjoy more fun in life. Batch production can be handed over to JLCPCB. Its standardized independent online ordering method only takes 12 hours for assembly. Once the PCB file is approved, the delivery of PCB+SMT can be completed the next day.

4. Quality assurance:

JLCPCB follows strict quality control measures to ensure that assembled PCBs meet the required standards. They perform visual inspections, automated optical inspections (AOI), and X-ray inspections, among other tests, to maintain high-quality production.

Why is JLCPCB PCB assembly your best choice?

JLCPCB PCB assembly service has always been committed to providing efficient, self-help services. The matching of orders is the highest frequency, and it is also the most critical technology to improve the efficiency of the effect. In 2021, JLCPCB set up a special project team to improve this automatic matching rate. They first created a system to measure whether the matching rate has indeed improved, and at the same time, they can quickly locate the problem of customer matching.

Case:

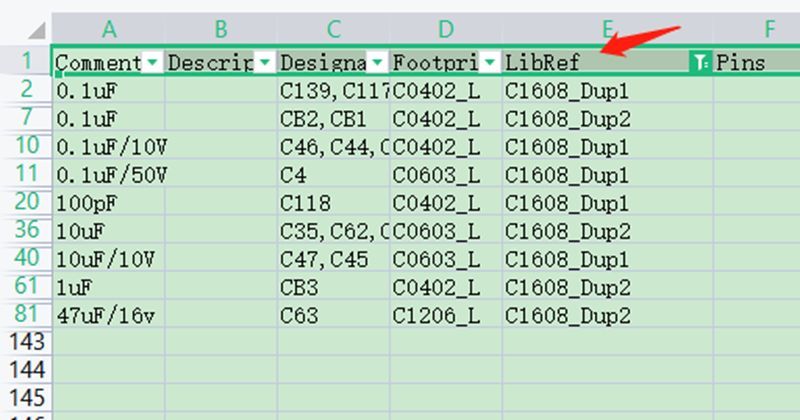

"We use the monitoring and debugging functions of our system, and we feel strange, according to the stock price, the package should match another C1525, how come it is C1608?"

"It is found that the matching of the diagnosis is the C number matching, and then when the customer contributes the customer number, we query the customer's BOM. The customer's library file is C1608, and we use C1608 first as the store's number."

JLCPCB spent time fixing compatibility issues with messy BOMs. To mine the product number, the success rate has been increased by 5%. It is difficult for technology to be beneficial to everyone, and they only speak with data. After 1 year of development, the auto-matching rate rose from 54% to 85%. Only 15% of parts need to be chosen by yourself when ordering PCBA on JLCPCB. Customers and salesmen have always been praised, and this matching rate also allows us to actively monitor problems.

SMT matching is still iterating, and JLCPCB will gradually improve it. It is estimated that JLCPCB SMT matching will increase by more than 6% points by the end of this month, which is estimated to be the highest level of matching rate in this industry.

JLCPCB - Engineers' best PCBA choice

Keeping an open mind and embracing every customer is the working attitude of JLCPCB. Customer opinions and feedback are the motors of the JLCPCB SMT project progress. Listening and communicating go both ways. JLCPCB serves 172 countries around the world, serving 1,000,000 +Customers, with higher than 99.97% On-time delivery, and lower than 0.23% Quality Complaint Rate. Remarks from PCBA customers:

JLCPCB has been committed to reducing PCB/PCBA costs, improving the ordering experience, and speeding up lead time and shipping. Many entrepreneur customers said JLCPCB helps them to improve their business through time and cost-saving.

"Besides PCB assembly, we like JLCPCB free gifts, packages, and people!"

"Open the box on the top side. We have cardboard, some bubble wrap, another layer of bubble wrap and another roller wrap. You can see PCB wrapped in bubble wrap and not just cardboard has some foam inside and some more power wraps of damage during shipping. It's almost impossible anyway".

In terms of the current performance, we would like to define JLCPCB SMT as a mode. SMT is no longer be a factory, but a connection in the production chain in the future. JLCPCB SMT remembers the original aim and will make every endeavor an extremely great customer experience. Saving your PCB assembly now and in the future, get JLCPCB $24 monthly SMT coupon!

[ADVERTISING COOPERATION]