I recently bought a led signal lamp for the gate on the Allegro, given in the subject. The lamp flashes in such a way that it goes out for a moment, and then it flashes for another moment like a strobe and so on. It is powered by 230v. Unfortunately, I am not satisfied with the amount of light that comes out of it. During the day and in the evening it is barely visible.

I have a lot of 230v led bulbs and LED panels and strips for lower voltages. Someone can know if it is easy to change this system to make the lamp shine stronger.

Thank you in advance for your help :)

Update:

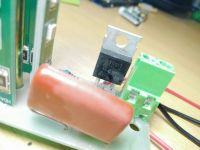

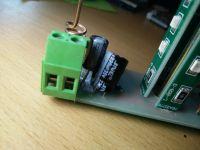

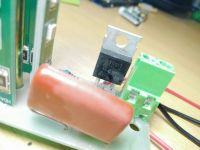

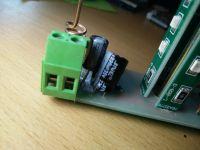

I checked it quickly and the output for the diodes is a little over 5v (for each of the 4 strips).

Is it possible to replace any resistor or other element and easily make it so that the output is 12 or 230v in order to mount other LEDs?

I have a lot of 230v led bulbs and LED panels and strips for lower voltages. Someone can know if it is easy to change this system to make the lamp shine stronger.

Thank you in advance for your help :)

Update:

I checked it quickly and the output for the diodes is a little over 5v (for each of the 4 strips).

Is it possible to replace any resistor or other element and easily make it so that the output is 12 or 230v in order to mount other LEDs?