FAQ

TL;DR: ABS ghost speeds up to 655 km/h and uneven sensor supply (1.76 V vs 0.8 V) indicate a rear-harness fault; "it shows me the speed of 655 km/h." [Elektroda, Maras13a, post #16806264]

Why it matters: This FAQ helps Renault Master III owners and techs quickly pinpoint ABS light causes after rear wheel‑speed sensor work.

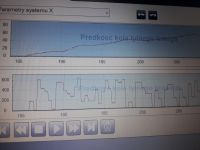

- Typical symptom: one rear wheel reports 20–600+ km/h while others track vehicle speed; ABS lamp then sets a fault. [Elektroda, Maras13a, post #16806040]

- Field-measured sensor feed: ~1.76 V on one rear channel vs ~0.8–0.9 V on the other suggests a side‑specific issue. [Elektroda, Maras13a, post #16806040]

- Proven fix case: open circuit from pump to sensor; replace loom section (near tank to sensor) with a twisted pair. [Elektroda, AdamOSA, post #18854270]

- ABS pump connector map: pins 1/25 = +12 V, 13/38 = ground, 32 = +12 V IGN, 26/14 = CAN, 17 = K‑line. [Elektroda, genek1000, post #19145810]

- Swap-test method: extend the known‑good side and read that channel while driving the opposite sensor to isolate loom vs sensor. [Elektroda, ptr92, post #16806147]

Quick Facts

- Typical symptom: one rear wheel reports 20–600+ km/h while others track vehicle speed; ABS lamp then sets a fault. [Elektroda, Maras13a, post #16806040]

- Field-measured sensor feed: ~1.76 V on one rear channel vs ~0.8–0.9 V on the other suggests a side‑specific issue. [Elektroda, Maras13a, post #16806040]

- Proven fix case: open circuit from pump to sensor; replace loom section (near tank to sensor) with a twisted pair. [Elektroda, AdamOSA, post #18854270]

- ABS pump connector map: pins 1/25 = +12 V, 13/38 = ground, 32 = +12 V IGN, 26/14 = CAN, 17 = K‑line. [Elektroda, genek1000, post #19145810]

- Swap-test method: extend the known‑good side and read that channel while driving the opposite sensor to isolate loom vs sensor. [Elektroda, ptr92, post #16806147]

What does it mean when a rear wheel shows 600+ km/h and the ABS light comes on?

It signals a corrupted wheel-speed signal, often from wiring. One Master III logged 655 km/h on a rear channel at low speed. That is classic “ghost speed” from a broken or shorted harness, not a mechanical tone ring issue. Verify by comparing side-to-side feeds and doing a guided swap test. [Elektroda, Maras13a, post #16806264]

How do I tell if the sensor or the harness is bad using a swap test?

Work from the known‑good side. Extend the left‑rear harness and plug it into the right‑rear sensor, then read the left‑rear channel. If readings normalize, sensor and crown are fine; the fault lies in the original right‑rear loom or controller path. [Elektroda, ptr92, post #16806147]

What voltage should I see at the rear wheel‑speed sensors?

On a reported Master III case, the left rear feed measured ~1.76 V while the right rear showed ~0.8–0.9 V. A persistent lower feed on one side points to a harness or channel issue, not a good sensor. Record both sides and compare. [Elektroda, Maras13a, post #16806040]

Which ABS pump pins supply power, ground, and diagnostics on Master III?

ABS connector quick map: pins 1 and 25 are permanent +12 V; pins 13 and 38 are grounds; pin 32 is +12 V after ignition; pins 26 and 14 carry CAN; pin 17 is K‑line. “2 thick red ones for 1 and 25 pin - +12V permanent.” [Elektroda, genek1000, post #19145810]

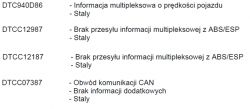

My scanner can’t connect to the ABS. What should I check first?

Confirm ABS power and grounds at the pump connector, then verify ignition feed at pin 32. Check network lines: CAN on pins 26/14 and K‑line on pin 17 to the OBD socket. A missing feed or open network will block diagnostics. [Elektroda, genek1000, post #19145810]

Where does the rear ABS loom commonly fail on Master III?

One fix report found an open circuit between the pump and the sensor, localized between the fuel tank area and the sensor plug. Replacing that section restored normal readings and cleared the fault. [Elektroda, AdamOSA, post #18854270]

Should I use a twisted pair for the wheel‑speed sensor repair?

Yes. The reported repair replaced the damaged section with a twisted pair to maintain signal integrity and reduce noise pickup. “We make a twisted pair.” Keep the twist consistent to the sensor plug. [Elektroda, AdamOSA, post #18854270]

How do I perform a 3‑step harness swap test to isolate the fault?

- Identify the channel that reads correctly (e.g., left rear).

- Extend that harness and plug it into the opposite sensor.

- Read the original channel’s live data while spinning the opposite wheel; normal data implicates the original loom on the faulty side. [Elektroda, ptr92, post #16806147]

Why did the fault stay on the right‑rear even after swapping sensors?

Because the issue isn’t the sensor. A user swapped connectors and still saw distortion tied to the right‑rear channel. That behavior points to a loom or channel feed fault on that side, not the sensor hardware. [Elektroda, Maras13a, post #16806166]

What is CAN bus in this ABS context?

CAN is the two‑wire network the ABS module uses to communicate with the vehicle and scan tools. On Master III, CAN connects through the security module to the OBD socket via ABS pins 26 and 14. Keep these lines intact for diagnostics. [Elektroda, genek1000, post #19145810]

Can low sensor feed voltage trigger the ABS light even when stationary?

Yes. Static readings showed 0 km/h, but once moving, the affected channel produced wild speeds. The same case measured ~0.9 V on the problem side versus ~1.76 V on the other, confirming an electrical fault. [Elektroda, Maras13a, post #16806040]

What additional data points help confirm a wiring fault?

Record live speed while hand‑spinning the wheel. One report saw 6–8 km/h when spinning by hand, yet the faulty channel also spiked to 655 km/h. This combination strengthens the diagnosis of a loom issue. [Elektroda, Maras13a, post #16806264]

After bleeding brakes the ABS lamp remains on—where should I start?

Start with electrical basics at the ABS: permanent +12 V, grounds, and ignition feed. Then check network integrity on CAN pins 26/14 and K‑line at pin 17 to the OBD path. Fix power/comms before deeper hydraulic checks. [Elektroda, genek1000, post #19145810]

What was the actual fix reported by someone with the same problem?

They found one wire had no continuity to the sensor. The solution was to replace the loom section from near the fuel tank to the sensor plug, using a twisted pair. Fault cleared afterward. [Elektroda, AdamOSA, post #18854270]