Hello everyone

Let me start with the fact that I recently started playing with induction heating, I made the heater on the generally circulating diagram of the ZVS heater, but on 2 IRFP260 transistors there is no craze, with 26V power supply I get almost 40A, it is enough to heat the M12 screw / 100 to almost 600C, here are some photos of the construction ...

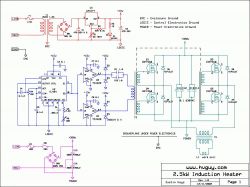

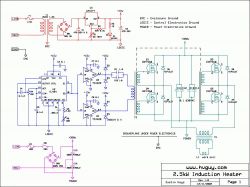

but I came across a simple layout with reportedly 2.5kW power on a full bridge with IRFP460, unfortunately without a description, I would like to ask your honorable colleagues whether it is worth building this system, is it correct, and any suggestions whether I can use TC4421 / TC4422 as drivers because I have these, and how many turns GDT do and on what core.

Many thanks in advance for your interest and any hints ...

Best regards.

Added after 7 [minutes]:

Of course, power supply without a doubler, a bridge and 2x12000uF / 250V filtration in series which will give 6000uF 500V, a bit low, but at the moment I have only 3 pcs of such capacitors, I have 2 pcs 2200uF / 450V so I can add them in parallel to it was 10400uF ...

Let me start with the fact that I recently started playing with induction heating, I made the heater on the generally circulating diagram of the ZVS heater, but on 2 IRFP260 transistors there is no craze, with 26V power supply I get almost 40A, it is enough to heat the M12 screw / 100 to almost 600C, here are some photos of the construction ...

but I came across a simple layout with reportedly 2.5kW power on a full bridge with IRFP460, unfortunately without a description, I would like to ask your honorable colleagues whether it is worth building this system, is it correct, and any suggestions whether I can use TC4421 / TC4422 as drivers because I have these, and how many turns GDT do and on what core.

Many thanks in advance for your interest and any hints ...

Best regards.

Added after 7 [minutes]:

Of course, power supply without a doubler, a bridge and 2x12000uF / 250V filtration in series which will give 6000uF 500V, a bit low, but at the moment I have only 3 pcs of such capacitors, I have 2 pcs 2200uF / 450V so I can add them in parallel to it was 10400uF ...