FAQ

TL;DR: On this Vectra C Z18XE, idle MAF returned to 8 kg/h and "everything works as it should" only after ECU replacement; P0170-11 and open-loop behavior traced to a failing Simtec 71.5. [Elektroda, balonik1990, post #17477268]

Why it matters: This FAQ helps Opel/GM Z18XE owners fix stubborn P0170-11 mix faults without wasting money on good sensors.

Quick Facts

- ECU: Simtec 71.5 hybrid mounted on the engine; known to fail. On LPG cars, replace Bank 1 O2 first. [Elektroda, kamyczek, post #17439384]

- Case outcome: After ECU swap, idle MAF read 8 kg/h; lambda oscillated; mix errors disappeared. [Elektroda, balonik1990, post #17477268]

- Loop behavior: After clearing, closed loop returns briefly, then reopens in ≤2 minutes as the fault sets warm. [Elektroda, balonik1990, post #17439366]

- Edge case: Downstream O2 held ~410 mV and no catalyst/second-probe error, even with the cat removed. [Elektroda, balonik1990, post #17461396]

- Initial data point: Idle MAF 21 kg/h (~1.35 V) at ~880 rpm on a 350,000 km, LPG-equipped car (Siemens 5WK9606). [Elektroda, balonik1990, post #17425432]

What actually fixed P0170-11 on this Vectra C Z18XE?

Replacing the Simtec 71.5 ECU solved it. After the swap, errors cleared, B1S1 started oscillating, and idle MAF settled at 8 kg/h. The engine ran smoothly with closed-loop control restored. No further mixture faults returned. [Elektroda, balonik1990, post #17477268]

How can I check if my MAF (Siemens 5WK9606) is the culprit?

Read MAF mass flow at hot idle with OP-COM. If readings stay high despite trying known-good MAFs, suspect the ECU. Confirm by monitoring B1S1 oscillation and loop status.

- Warm engine; note MAF kg/h and loop state.

- Clear codes; watch if loop closes and MAF normalizes.

- If sensors check out yet faults persist, substitute ECU for confirmation. [Elektroda, balonik1990, post #17477268]

Why does the O2 loop flip open once the engine warms?

In this case, when the fault stored, the ECU kept the loop open. Clearing the error briefly restored closed-loop, then it reopened as temperature rose. The switch often occurred around 50–60°C. The loop stayed open until the code was cleared again. [Elektroda, balonik1990, post #17440572]

Does LPG use affect sensors, and what should I replace first?

Yes. LPG can age the front O2 sensor faster and skew mixture control. The forum advice here: "the first thing I would replace is the o2 bank1 sensor." Also inspect EGR and detonation issues that can stress the MAF. [Elektroda, kamyczek, post #17439384]

My downstream O2 stays near 410 mV and no catalyst error, even with no cat. What does that mean?

That pattern points to a failed ECU, not a healthy sensor system. As one member summarized, "A beaten driver." A stuck mid-voltage on B1S2 with no catalyst/second-probe DTC after decat is a strong ECU clue. [Elektroda, robokop, post #17461359]

Could a weak battery cause this P0170 or the open-loop behavior?

Not in this case. The recurring mix fault and open-loop behavior persisted until the ECU was replaced. After ECU swap, normal operation returned and the issue disappeared. Battery condition was not the root cause here. [Elektroda, balonik1990, post #17477268]

What idle MAF reading should I expect on a healthy Z18XE?

Use the case as a reference. After the fix, this Z18XE showed about 8 kg/h at warm idle with stable closed-loop operation. If your value is close and the O2 oscillates, the MAF is likely fine. [Elektroda, balonik1990, post #17477268]

Which initial measurements suggested a bad MAF here?

The car reported 21 kg/h at idle (~880 rpm) with about 1.35 V MAF output. The vehicle had 350,000 km and LPG, which can bias suspicion toward MAF wear. These data led the owner to try MAF swaps first. [Elektroda, balonik1990, post #17425432]

Is the Simtec 71.5 ECU a known failure point on Z18XE?

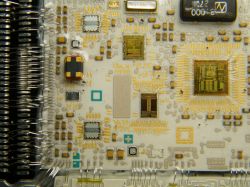

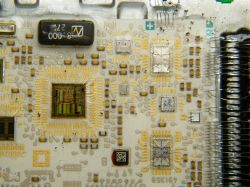

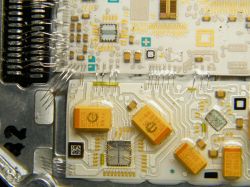

Yes. It is an engine-mounted hybrid ECU and can fail, mimicking sensor faults. As a member noted, "you have a simtec 71.5 ... which unfortunately can break down with very similar end symptoms." Heat and vibration can contribute. [Elektroda, kamyczek, post #17439384]

Is opening the ECU to inspect wire bonds helpful?

It can reveal obvious damage, but not all failures are visible. Here, the owner inspected the aluminum bridges and found no breaks in the gel. Intermittent or internal component faults can still remain undetected by visual checks. [Elektroda, balonik1990, post #17447518]

Could EGR or spark plugs be the cause of a mix error like P0170?

They can contribute. The thread recommends checking EGR operation and replacing spark plugs if needed. Also verify lambda probe behavior and MAF readings. The ECU itself can also misread sensors under vibration. [Elektroda, kamyczek, post #17425486]

How did the front O2 (B1S1) behave during the fault?

B1S1 oscillated briefly after clearing the code, then stalled near 20 mV as the engine warmed. The ECU then forced open loop and the engine ran unevenly. Clearing the error restored closed loop for a short time. [Elektroda, balonik1990, post #17440572]

Which OP-COM live data should I watch during diagnosis?

Monitor MAF mass flow (kg/h), B1S1 voltage, and closed/open loop status. Track coolant temperature and RPM to see when the loop opens. Watching these together shows whether clearing codes temporarily restores closed loop before the fault returns. [Elektroda, balonik1990, post #17439366]

I swapped MAFs and replaced O2 sensors, but the fault persists. What next?

Consider the ECU. In this case, multiple used MAFs and two front O2 sensors (including new Delphi) did not fix P0170. Only replacing the Simtec 71.5 ECU restored normal readings and closed loop. [Elektroda, balonik1990, post #17461254]