FAQ

TL;DR: Planning a cylinder head is required only when flatness exceeds the maker’s tolerance; typical corrective grinding removes <1 mm and costs 60–550 zł [Elektroda, robokop, #7199457; Sodekso, #7201604]. “The thickness of the gasket is selected according to piston protrusion” [Elektroda, robokop, post #7201099]

Why it matters: Wrong machining or gasket choice can hike compression, causing detonation or cracked diesel heads.

Quick Facts

• Corrective planing depth: 0.05–1 mm typical [Elektroda, robokop, post #7199457]

• Motorsport “extreme” planing: up to several mm removed [Elektroda, robokop, post #7199457]

• VW 1.9 TDI heads: factory forbids resurfacing; replace instead [Elektroda, robokop, #7199457; ftp.kowal, #17521642]

• Multi-layer steel gasket range: ∼0.5 mm between thinnest and thickest options [Elektroda, robokop, post #7201952]

• Polish CNC planing prices: 60 zł (Łódź) – 550 zł (Katowice) [Elektroda, Anonymous, #7201614; Sodekso, #7201604]

Do I have to plane the head every time I replace the head gasket?

No. Measure flatness first; if it is within the manufacturer’s limit (often ≤0.03 mm over 150 mm) resurfacing is unnecessary [“Toyota Engine Repair Manual”]. Otherwise perform corrective grinding (<1 mm) [Elektroda, robokop, post #7199457]

How do I quickly check if my cylinder head is flat?

- Clean the mating surface.

- Lay a precision straightedge diagonally and lengthwise.

- Insert 0.03 mm feeler gauges under the edge; any gap that accepts the gauge means the head needs machining [Elektroda, MakroSerwis, post #7203270]

What’s the difference between corrective and extreme head planing?

Corrective planing removes up to 1 mm to restore flatness and keeps factory compression [Elektroda, robokop, post #7199457] Extreme planing shaves several mm to raise compression for racing, risking detonation and crank failure [Elektroda, Anonymous, post #7201811]

Why is planing prohibited on some VW turbodiesel heads?

VW TDI heads have minimal valve-to-piston clearance; material removal upsets this geometry. The service bulletin specifies replacement instead of machining [Elektroda, robokop, #7199457; ftp.kowal, #17521642].

Does planing automatically mean I need a thicker gasket?

No. Gasket thickness is chosen by measuring piston protrusion, not by head material removed [Elektroda, robokop, post #7201099] The available gasket range is only about 0.5 mm, so it cannot offset a 1 mm cut [Elektroda, robokop, post #7201952]

How much can I plane before touching valve seats?

Most aluminum heads allow about 0.2–0.3 mm before seat recess must be checked; over 0.5 mm may require seat machining or thicker gasket in diesels [Elektroda, Anonymous, post #7201962]

What happens if I reuse a ‘banana’-shaped head without machining?

Warped heads cause uneven clamp load, leading to repeat gasket failure and coolant loss. Severe warping can crack between valve seats [Elektroda, PORTOS23, #7201894; robokop, #7201952].

Could planing create camshaft or alignment problems?

Yes. On long six-cylinder heads, removing material shifts cam bore alignment and can snap the cam during installation [Elektroda, Megawe, post #7201484]

How much does professional head planing cost and what machines are used?

In Poland, grinding on a semi-automatic plane grinder costs around 60 zł, while CNC milling was quoted at 550 zł [Elektroda, Anonymous, #7201614; Sodekso, #7201604].

Is milling or grinding better for resurfacing?

Milling leaves fine grooves that help gasket grip; grinding gives a smoother Ra value. Both are acceptable if surface roughness meets the gasket maker’s spec (usually Ra 1.5–3.0 µm). MakroSerwis prefers light milling ‘to whitewash’ [Elektroda, MakroSerwis, post #7203270]

Are oversize gaskets available for gasoline engines?

Generally no. Petrol engines rely on uncut heads to maintain chamber volume; manufacturers sell only standard thickness MLS gaskets [Elektroda, robokop, post #7202055]

How do I select the correct multi-layer steel (MLS) gasket after block work?

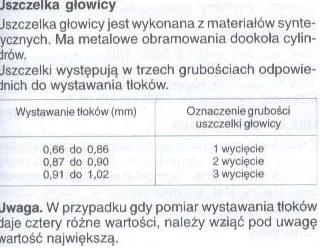

Measure piston protrusion at four points:

- Set dial gauge on TDC piston.

- Zero gauge on block deck.

- Record protrusion; average readings.

- Match value to manufacturer’s notch code (e.g., 0.66–0.86 mm = 1-notch) [Elektroda, marek1977, post #7201975]

What are signs of detonation after excessive planing?

Ping under load, blown spark-plug electrodes, and melted piston crowns appear because compression ratio rose too far [Elektroda, Anonymous, post #7201811]

When should I replace the head instead of planing it?

Discard heads with cracks between valve seats, severe ‘banana’ warp, or when required cut exceeds factory maximum (often 0.3 mm for TDI) [Elektroda, PORTOS23, #7201894; ftp.kowal, #17521642].