Hello, sorry for refreshing a bit of a historic theme ....

Quite an interesting topic, but unfortunately there is little information about it.

Seats break down and the actuator can be cheaply and easily bought ...

I also had a problem with the armchair. Actuator lost pressure - frequent malfunction of the seat up and down valve. I analyzed the situation and came to the conclusion that, as a technical person, I would replace the shock absorber / cylinder / strut myself. :idea:

I bought an actuator for PLN 25 and problems started ... :|

Well, it's a trivial matter ... you take off what you need, replace the actuator and put everything back together, you don't even have to try too much, because you can't put it together otherwise.

Unfortunately, according to my observations, without the equipment and a bit of patience, things look rather poor.

For me, of course, nothing could be painlessly disassembled and the seemingly simple topic turned into a troublesome problem.

And the spouse's whining that, as usual ...

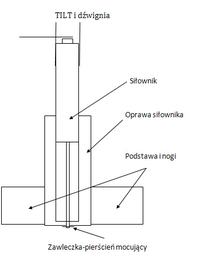

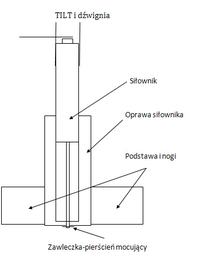

Finally, I did so, from the bottom of the chair I took off the pin / washer that fixes the piston-actuator rod - it is such a plate attached around the rod, the end of which can be seen from the bottom in the central part of the stand. At that time, I had a seat that folded out into two elements: a base with a part (housing) of the actuator and a separate backrest with the TILT mechanism and actuator (cylinder plus piston).

And here, unfortunately, equipment was needed. The oils and the hammer did not help. After two days of efforts (with home methods in the block), I squeezed the sleeve out of the base only on the hydraulic press and tugged the actuator out after a few minutes of struggle with the help of a large table vise, a hammer and a piece of hard rod, Through which I hit the bushing (TILT base) with a hammer sitting on the actuator .

In my case, the cylinder was completely dead (the piston could be moved with your fingers without resistance), so I was not afraid to screw it into a vice, when the cylinder holds the pressure, I advise you to be careful ... the Chinese mentioned above ....

I looked at the mounting of the actuator, because I also had the idea that if I do not tear at the vice, I will unscrew the TILT from the seat and from the top (through this sleeve) I will push the actuator on the press with something - it's a bad thing, the "paw" for lifting / lowering the seat is flat for me and there is no access to the actuator from the top ... So the push-out from the top rather comes off.

I have prepared a simple diagram of what it looks like in my armchair.

Good luck....

And, one more thing, the result of my home guerrilla activities is the cracking of the polymer cover of one of the legs of the stand ... I was sure that it was a bit more solid, I leaned the stand against the edge of the table top and tapped the base of the actuator with a hammer - on the first tap, the cover broke. .. and the actuator did not move. I will temporarily stick it with black electrical tape, but in some time the chair will be replaced ...

Attachment corrected!

Attachment corrected!

[_P_]