Hello,

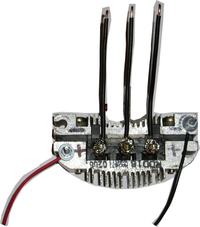

I have such alternator Magneti Marelli 14V 60A:

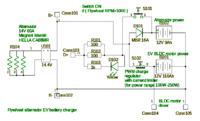

Successfully tested it by connecting (B+ and B-) it to battery (B101/B102) and also (D+) to battery (B101/B102) via those 2 resistors (R101 and R102).

When alternator speeds up D102 diode light nice goes low and alternator turns on...

But, i have no controll how much power or how big current will flow to connected battery from alternator while it has built in regulator.

This what I'd like to do is what I've showed on schema above-limit output power to predefined level lets say 150W... because of i'd like to use flywheel powered by human and try to store energy in it and switch alternator only when its RPM is above eg. 1000 (to be determined for this model) while I will have power needed to charge big EV battery (B101).

Small battery (B102) is only buffer there for powering alternator start and will be fully charged almost all the time, so I expect very small power needed to charge it, so voltage drop on diode D101 before this battery B102 is OK while it will work in buffer mode (acid or gel battery).

The big one (B101) may be discharged much more (while used by EV BLDC motor), so more current needed and without any charge regulator (marked S102) maybe alternator regulator will try to get more power from alternator which simply will not be available, while it is no longer used in car, but in human powered EV bike, so RPM will quickly drop.

That is why I'd like to make another switch (S101) controlled by small device which will switch it ON only when RPM is above alternator turn ON speed...

Of course, I know how to limit current charge in this big battery (B101), but I'm NOT SURE, whether I can switch ON alternator (D+) via switch (S101) when alternator has speed lets say 2000 RPM and then switch S101 OFF when RPM drops to 999 RPM-without damage of build in regulator?

So my idea was to use just 2 batteries like in this draw (small battery B102 secured by diode to be not discharged by low voltage on big baterry B101 during charging) and simply DO NOT disconnect ALL batteries from alternator (when it is turned on) using PWM for current regulation, but just only ONE-this big one B101 110Ah.

Maybe, there is another solution howto bypass alternator built in regulator to limit its output power, based on its RPM?

What do you think about it?

I have such alternator Magneti Marelli 14V 60A:

Successfully tested it by connecting (B+ and B-) it to battery (B101/B102) and also (D+) to battery (B101/B102) via those 2 resistors (R101 and R102).

When alternator speeds up D102 diode light nice goes low and alternator turns on...

But, i have no controll how much power or how big current will flow to connected battery from alternator while it has built in regulator.

This what I'd like to do is what I've showed on schema above-limit output power to predefined level lets say 150W... because of i'd like to use flywheel powered by human and try to store energy in it and switch alternator only when its RPM is above eg. 1000 (to be determined for this model) while I will have power needed to charge big EV battery (B101).

Small battery (B102) is only buffer there for powering alternator start and will be fully charged almost all the time, so I expect very small power needed to charge it, so voltage drop on diode D101 before this battery B102 is OK while it will work in buffer mode (acid or gel battery).

The big one (B101) may be discharged much more (while used by EV BLDC motor), so more current needed and without any charge regulator (marked S102) maybe alternator regulator will try to get more power from alternator which simply will not be available, while it is no longer used in car, but in human powered EV bike, so RPM will quickly drop.

That is why I'd like to make another switch (S101) controlled by small device which will switch it ON only when RPM is above alternator turn ON speed...

Of course, I know how to limit current charge in this big battery (B101), but I'm NOT SURE, whether I can switch ON alternator (D+) via switch (S101) when alternator has speed lets say 2000 RPM and then switch S101 OFF when RPM drops to 999 RPM-without damage of build in regulator?

So my idea was to use just 2 batteries like in this draw (small battery B102 secured by diode to be not discharged by low voltage on big baterry B101 during charging) and simply DO NOT disconnect ALL batteries from alternator (when it is turned on) using PWM for current regulation, but just only ONE-this big one B101 110Ah.

Maybe, there is another solution howto bypass alternator built in regulator to limit its output power, based on its RPM?

What do you think about it?