Hello,

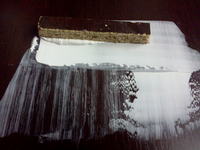

- I have already cut a hole in the countertop, now, according to the instructions, I have to put silicone on the edge of the hole and put a sink on it. What's the problem? The fact that the sink is made of a conglomerate, so heavy. Its circumference is 10 mm larger than the hole in the table top, so when I insert this heavy table top, the silicone will spread beyond its outline - onto the table top. having some experience with silicone, I know that this excess cannot be removed from the countertop. In a word, the table top becomes more or less dirty with this silicone.

Question: how is it done professionally, - can you cover the edge of the countertop on the border with the sink with a painter's tape? The table top is inexpensive, it is ordinary laminated chipboard, but I would not like to destroy it.

greetings

- I have already cut a hole in the countertop, now, according to the instructions, I have to put silicone on the edge of the hole and put a sink on it. What's the problem? The fact that the sink is made of a conglomerate, so heavy. Its circumference is 10 mm larger than the hole in the table top, so when I insert this heavy table top, the silicone will spread beyond its outline - onto the table top. having some experience with silicone, I know that this excess cannot be removed from the countertop. In a word, the table top becomes more or less dirty with this silicone.

Question: how is it done professionally, - can you cover the edge of the countertop on the border with the sink with a painter's tape? The table top is inexpensive, it is ordinary laminated chipboard, but I would not like to destroy it.

greetings