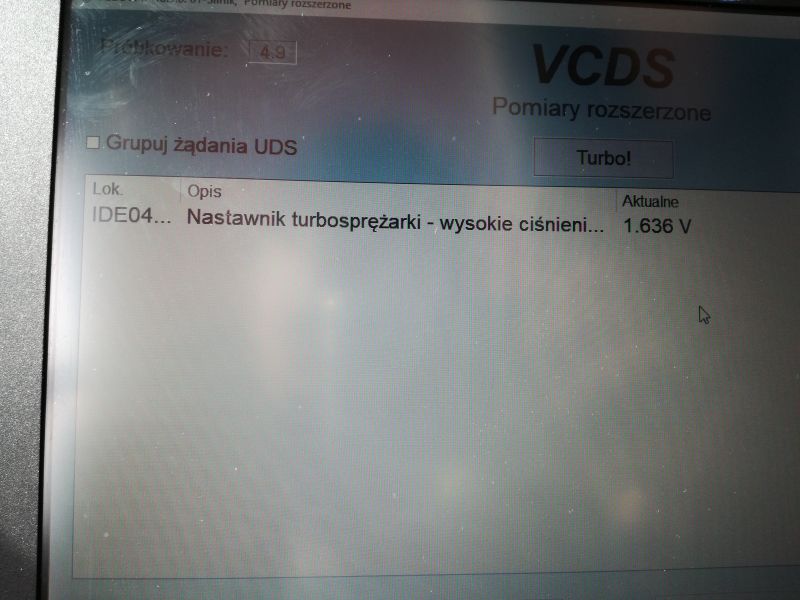

Hello, I have a problem with the regulation of the "barbell" turbine in Vw Golf 1.6tdi 2010. The old barbell had a damaged bellows and I was wrong: p0299 Turbo / Super Charger Underboost. After replacing with a new one, setting the new one in the same position (counting the scrolls on the banner) when the engine is running, there is an error in the adjustment range (I do not remember the exact code) and burning of the glow of candles. I need a barbell regulation guide, I think there's a problem here ...

Ps. The barbell is new from the dealer.

Ps. The barbell is new from the dealer.