Hello.

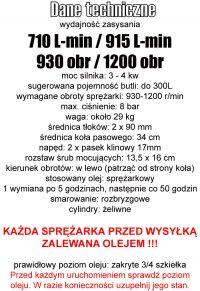

I am starting to build a compressor for a cabin sandblaster, so I care about the highest possible efficiency of the compressor, I have a Tamel skg-100l2 ik-396 220 / 380v engine, 3kw 2880rpm, I would like to use a 3-piston compressor, but the engine power suggested by the manufacturer is 7 , 5 kw and the air pump speed is about 980 r / min, max suction capacity 1370L / min, piston diameter 90 mm, pulley diameter 34 cm. Will this engine be able to power this compressor?

I am starting to build a compressor for a cabin sandblaster, so I care about the highest possible efficiency of the compressor, I have a Tamel skg-100l2 ik-396 220 / 380v engine, 3kw 2880rpm, I would like to use a 3-piston compressor, but the engine power suggested by the manufacturer is 7 , 5 kw and the air pump speed is about 980 r / min, max suction capacity 1370L / min, piston diameter 90 mm, pulley diameter 34 cm. Will this engine be able to power this compressor?