Hello

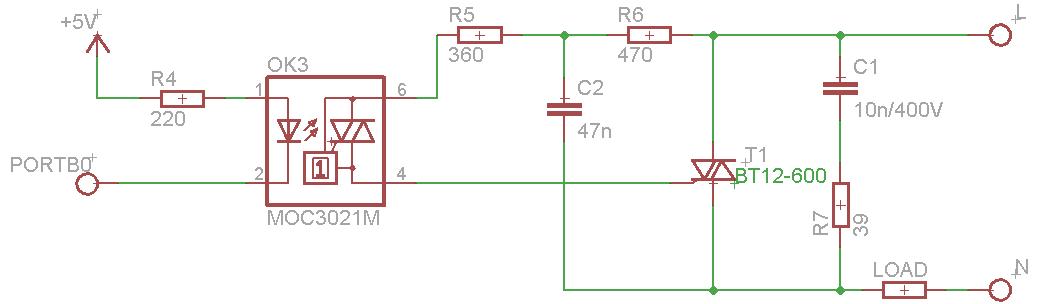

I have read many topics about fan speed control, but I can't tell what options I have in controlling this fan. Please, let me know if I can apply phase or group control here, or rather only the inverter is at stake. I care about the lowest possible RPM and to be able to control the RPM from the microcontroller. I have already tried with group control - however, the engine had clearly uneven revs (you could hear when it gets power) while with phase control it was possible to go down to low revs, however, the engine squeaked slightly and I do not know if it is the fault of the program or maybe I should not use such regulation in this blower .

Regards.

I have read many topics about fan speed control, but I can't tell what options I have in controlling this fan. Please, let me know if I can apply phase or group control here, or rather only the inverter is at stake. I care about the lowest possible RPM and to be able to control the RPM from the microcontroller. I have already tried with group control - however, the engine had clearly uneven revs (you could hear when it gets power) while with phase control it was possible to go down to low revs, however, the engine squeaked slightly and I do not know if it is the fault of the program or maybe I should not use such regulation in this blower .

Regards.