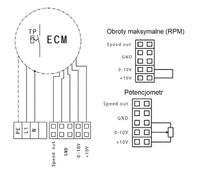

I have an EC motor in the recuperator with 0-10V control. When the 10V jumper is closed with the 0-10V jumper, the engine works at maximum speed.

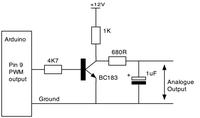

Can you control this voltage with arduino via PWM?

Is it enough to connect a transistor, e.g. BD139, to the PWM pin on the arduino?

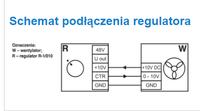

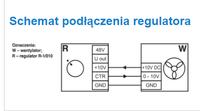

I enclose a picture of how regular adjustment looks like with the Regulator R-1/010.

Can you control this voltage with arduino via PWM?

Is it enough to connect a transistor, e.g. BD139, to the PWM pin on the arduino?

I enclose a picture of how regular adjustment looks like with the Regulator R-1/010.