FAQ

TL;DR: Two checks solve most “service light + no fill” cases: “Start by checking the heater for passage and leakage to ground.” [Elektroda, h jaworski, post #16737105]

Why it matters: This FAQ helps Polar PTL 1109 owners diagnose a post-warranty service-light fault where the pump stops and the washer won’t take water.

Quick Facts

- Symptom cluster: SERVICE lamp with five LEDs (400, 1g, 6g, 9g, 12g) reported. [Elektroda, Dental, post #16738371]

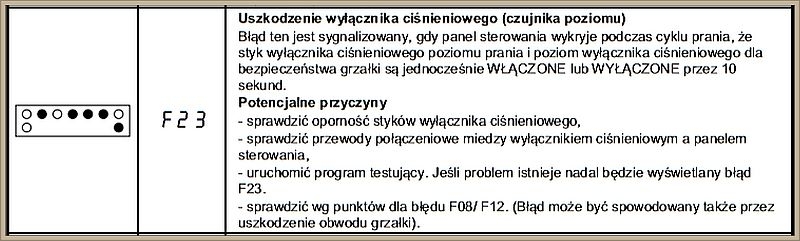

- Code hint: That LED pattern was identified as error F23 (pressure/hydrostat circuit issue). [Elektroda, nares, post #16738563]

- No water intake noted: “silent as a grave,” suggesting fill or pressure-sensing fault. [Elektroda, Dental, post #16737591]

- First diagnostic step advised: check heater continuity and insulation to ground. [Elektroda, h jaworski, post #16737105]

- Root cause candidate: clogged pressure-chamber/reservoir at the hose end lowers hydrostat pressure. [Elektroda, homer2.13, post #20032846]

What does the SERVICE light with several LEDs (400, 1g, 6g, 9g, 12g) mean on a Polar PTL 1109?

That LED set has been read as error F23, which points to the pressure/hydrostat sensing path. It often relates to blocked air paths, wiring to the pressure switch, or the pressure switch itself. One user reported those exact LEDs alongside the SERVICE lamp. Confirm the pressure hose and chamber are clean before replacing parts. “Error F23, river topic.” indicates a known, recurring pressure-circuit issue on this platform. [Elektroda, nares, post #16738563]

My washer won’t take water and stays silent—where should I start?

Documented cases link “no fill + SERVICE” to pressure-sensing or inlet path issues. Verify inlet water is on, screens are clear, and measure inlet valve coil continuity. If coils check out, inspect the pressure hose and the tub-side chamber for sludge. A blocked chamber prevents pressure rise, so the control never authorizes fill. Users described the machine as “silent as a grave,” matching an intake or sensing fault. [Elektroda, Dental, post #16737591]

How do I check the heater safely on this model?

Unplug the washer. Remove heater connectors. Measure heater resistance for continuity, then megger or measure insulation to ground. A ground fault can trigger the service light and halt the cycle. As one expert said, “Start by checking the heater for passage and leakage to ground.” If the heater fails either check, replace it before chasing other faults. [Elektroda, h jaworski, post #16737105]

I already replaced the heater and pressure switch; the error persists. What next?

If parts swaps didn’t help, inspect the pressure circuit end-to-end. Clean the tub-side pressure chamber and ensure the hose isn’t kinked or porous. A clogged reservoir can defeat a new pressure switch by starving it of pressure. Also reseat connectors and look for broken wires around the switch. “Replacing the pressure switch also failed” when the blockage remained. [Elektroda, Dental, post #16745480]

Could a clogged pressure-chamber/reservoir really cause F23?

Yes. If the chamber at the hose end is clogged, pressure won’t reach the hydrostat, and the control flags a pressure fault. One contributor suspected exactly this scenario and called it out as the likely cause behind persistent F23-like behavior after parts replacement. Clean the chamber thoroughly before retesting. [Elektroda, homer2.13, post #20032846]

What is the hydrostat (pressure switch) in a washing machine?

The hydrostat is a diaphragm switch that changes state based on air pressure from the tub via a small hose. It tells the control when the water level is correct. If the hose or the reservoir is clogged, the switch reads wrong. This leads to fill rejection and service faults such as F23. Cleaning the reservoir often restores correct readings. [Elektroda, homer2.13, post #20032846]

How can I read Polar PTL 1109 fault indications without a display?

Watch the LEDs. A user documented the SERVICE lamp together with five LEDs (400, 1g, 6g, 9g, 12g). This combination was interpreted as F23. Note the exact LED set and compare to a code chart for this platform. Consistent patterns help isolate the failing subsystem, like the pressure circuit. Photograph the panel to avoid miscounts. [Elektroda, Dental, post #16738371]

Is 3.7 kΩ OK for an inlet valve coil on this washer?

One user reported measuring about 3.7 kΩ and asked if it was OK. Use it only as a reference, not a standard. Compare both coils; significant mismatch suggests a bad valve. Edge case: a coil can pass a static ohms test yet stick mechanically when energized. If in doubt, bench-test with controlled AC and proper isolation. [Elektroda, Dental, post #16738371]

Why does the pump start, then stop, and the SERVICE light comes on?

The control may initiate drain, then halt when it detects an invalid pressure state. If the hydrostat path is blocked or misread, the controller cannot confirm levels and aborts. Clearing the pressure chamber and hose often resolves the start-then-stop behavior associated with F23-type faults. Recheck after cleaning before replacing boards. [Elektroda, nares, post #16738563]

Should I replace the pressure sensor without testing?

No. As one expert warned, replacing sensors blindly risks mismatches and recurring faults. Verify the heater, check wiring, and clean the pressure circuit first. Parts from other machines may differ, creating new problems. Test the old sensor once the hose and reservoir are clean to avoid unnecessary expense. [Elektroda, h jaworski, post #16737221]

Quick 3-step: how do I clear a clogged pressure chamber on the PTL 1109?

- Unplug the washer; remove the top.

- Detach the small pressure hose at the tub; remove sludge from the tub-side chamber.

- Flush the hose, refit securely, and run a short fill test.

A clogged reservoir at the hose end is a known culprit. [Elektroda, homer2.13, post #20032846]

Why did new parts not revive my machine right after warranty?

The thread shows that swapping the heater and pressure switch did not cure the fault until the pressure path was addressed. Post-warranty failures often combine minor blockages with protective logic. Focus on cleaning and verifying the hydrostatic path before suspecting electronics. This approach prevented repeated part swaps in similar cases. [Elektroda, Dental, post #16745480]