Hello, interested

In Bosch / Siemens dishwashers having a washing pump with a heater; in the older type, i.e. those that had a two-circuit heater with two segments of about 11? and a plug of old type 7 pin for wide connectors and a newer type where there was a one-circuit heater about 22? and two plugs, i.e. one for a 3-pin heater with wide connectors and NTC plug smaller.

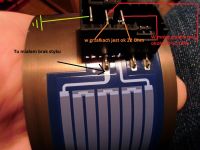

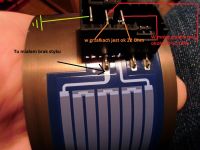

The question is: did anyone meet with such a newer type of heater that was single-segmented and had a resistance of around 11?? I have such a heater from a pump that has such resistance, i.e. 10-11? - does it mean that the system takes about 23A of current and has a power of over 5kW? I watched the heater with a glass magnifying exactly the path and there are no visible defects or short circuits to make such a small resistance. The heater had a break at the heating bar with the pin, now it has to be replaced with a new heater, which usually have a resistance of around 22?. I wonder if with this solution will be warming up the water or after washing up the E09? Below I allowed myself to copy from the graphic and edit the picture.

PS.

My heater windings are in green color, and those with drawings in blue, the older heaters two segments of 11? each had a green color of insulation.

In Bosch / Siemens dishwashers having a washing pump with a heater; in the older type, i.e. those that had a two-circuit heater with two segments of about 11? and a plug of old type 7 pin for wide connectors and a newer type where there was a one-circuit heater about 22? and two plugs, i.e. one for a 3-pin heater with wide connectors and NTC plug smaller.

The question is: did anyone meet with such a newer type of heater that was single-segmented and had a resistance of around 11?? I have such a heater from a pump that has such resistance, i.e. 10-11? - does it mean that the system takes about 23A of current and has a power of over 5kW? I watched the heater with a glass magnifying exactly the path and there are no visible defects or short circuits to make such a small resistance. The heater had a break at the heating bar with the pin, now it has to be replaced with a new heater, which usually have a resistance of around 22?. I wonder if with this solution will be warming up the water or after washing up the E09? Below I allowed myself to copy from the graphic and edit the picture.

PS.

My heater windings are in green color, and those with drawings in blue, the older heaters two segments of 11? each had a green color of insulation.