FAQ

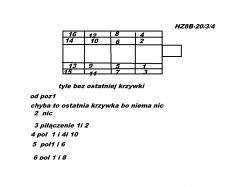

TL;DR: HZ8B‑20/3/4 exists in at least 3 versions, and “the symbol … does not necessarily define a specific switch.” Rewire by diagram, then set cams correctly. [Elektroda, wurba, post #18527702]

Why it matters: This FAQ helps owners fix 230/400 V switching and cam orientation on Einhell Euromaster PES 160F and similar welders.

Quick Facts

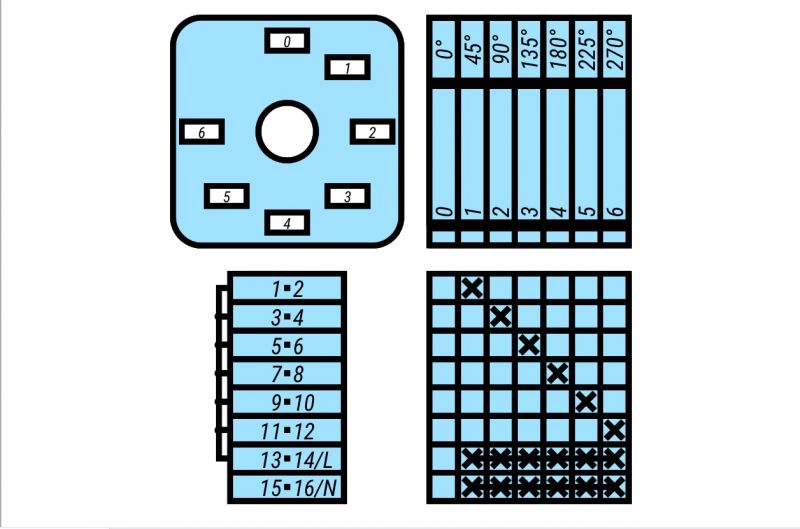

- HZ8B‑20/3/4 variants: 1‑position (0/230 V), 3‑position (230/0/400 V), and 6‑position types. [Elektroda, wurba, post #18527702]

- Example 230/400 layout that worked after tracing and rewiring was confirmed by a user. [Elektroda, damek4, post #20523095]

- Typical primary resistance observed: ~0.4 Ω at 230 V vs ~0.6 Ω at 400 V. [Elektroda, Nix, post #20523073]

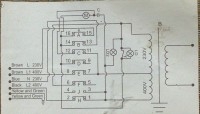

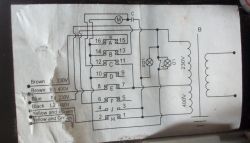

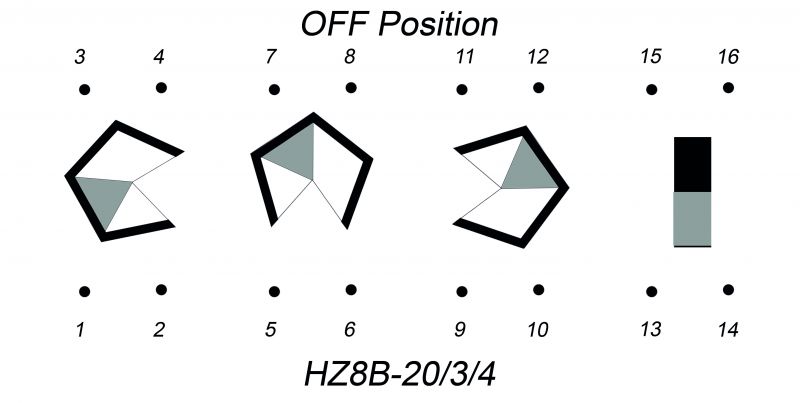

- Example contact shorts used on Einhell setup: 400 V: 1‑2,5‑6,9‑10,13‑14; 230 V: 3‑4,7‑8,11‑12,15‑16. [Elektroda, damek4, post #20521155]

- Reported replacement switch cost: approx. 200 PLN. [Elektroda, programator12, post #16992410]

How do I wire an HZ8B‑20/3/4 for 230 V and 400 V on an Einhell PES 160F?

Start from a verified diagram, then set cam orientations to match the contact sequence. One owner fixed 230/400 V, indicators, and fan by rearranging cams (four seating options) and moving one terminal link. Document your links before changes. “It worked, the welder works at 230 and 400.” [Elektroda, 123zbycho, post #16993070]

Are all HZ8B‑20/3/4 switches identical inside?

No. The marking doesn’t define one internal scheme. Users report at least three versions with different switching counts and positions. Always get the specific wiring diagram for your unit and verify the switching map before swapping parts or jumpers. [Elektroda, wurba, post #18527702]

Does the Einhell BT‑GW 150 include a 230/400 V selector?

No. It’s a 230 V‑only machine, so it lacks a 230/400 V switch. Do not expect dual‑voltage behavior or attempt series/parallel primary changes on that model. Use the correct single‑voltage wiring. [Elektroda, Nix, post #17723620]

What happens if all cams are installed the same way?

A previous owner had all cams aligned identically. The welder then worked only at 400 V. Mixed cam orientation is required to realize different contact closures across positions. This is a common failure mode after disassembly. [Elektroda, 123zbycho, post #16994355]

Which contacts should close in 230 V vs 400 V on the example Einhell setup?

Example used by a forum member: 400 V shorts 1‑2, 5‑6, 9‑10, 13‑14; 230 V shorts 3‑4, 7‑8, 11‑12, 15‑16. Bridges used: 1‑3, 7‑11, 10‑14, 14‑16. Treat as a template, then verify continuity on your switch. [Elektroda, damek4, post #20521155]

My measured primary resistance is 0.4 Ω at 230 V and 0.6 Ω at 400 V—is that right?

Yes. That pattern makes sense because the 400 V configuration places more copper in series, increasing resistance. Use a meter suitable for sub‑ohm readings to avoid error. A contributor confirmed 0.6 Ω corresponds to 400 V. [Elektroda, Nix, post #20523073]

Pin 6 joins pin 5 on the diagram, but pin 5 seems unused—normal?

In some diagrams, a paired contact is shown though one side is not externally wired in certain positions. That can leave pin 5 floating at 230 V while 6 is the active feed. Verify with a continuity test per switch position. [Elektroda, wojtek 9007, post #16987021]

What if my transformer has four primary leads but the middle pair is tied together?

That indicates two primary halves with a common junction. You can realize 230 V (parallel) and 400 V (series) by routing through the selector per the wiring map. Check your tie point and measure continuity before powering. [Elektroda, damek4, post #20522991]

How can I confirm a rewired selector actually works before welding?

Trace every input and output to the switch, correct any mis‑routes, and re‑measure. One user retraced, reconnected, and reported everything worked afterward. Only then apply mains and test open‑circuit secondary. [Elektroda, damek4, post #20523095]

What secondary voltage should I expect when testing?

A user saw about 47 V on the secondary and could weld. Exact voltage depends on tap and design. Verify against your nameplate or manual if available. Record readings per position for repeatability. [Elektroda, 123zbycho, post #16987726]

Is there a simple three‑step method to rebuild and orient the cams?

- Label every wire and take photos of the terminal links.

- Bench‑test the bare switch, mapping which contacts close in each position.

- Refit cams to achieve the needed 230/0/400 sequence, then reinstall and verify indicators/fan. [Elektroda, 123zbycho, post #16993070]

I lost the last cam’s position—how should it behave through positions 1–6?

One owner noted transitions between terminals 15–16 and 13–14 across positions 1–6, with no transition at position 0. Use a continuity map to restore the intended sequence before wiring. [Elektroda, programator12, post #16993993]

Can I buy a cheaper HZ8B‑20/3/4 and move my external jumpers over?

Not safely without confirming internals. Experts insist on a wiring diagram because HZ8B‑20/3/4 does not define the same contact system. Verify switch logic first, then adapt jumpers if it matches. [Elektroda, Nix, post #17710907]

What’s a realistic budget for replacing this selector?

A forum user reported about 200 PLN for a new switch. Prices vary by supplier and version. Factor in time for mapping, since variants differ. Keep your old links as spares. [Elektroda, programator12, post #16992410]

Why do some versions show three vs four active contacts at 230 V or 400 V?

Different internal wafers close different numbers of poles per position. Some add always‑on auxiliary poles for lights or fans. “You must have a switch wiring diagram.” [Elektroda, Nix, post #17710907]

After fixing cam order, should the fan and lights work on both voltages?

Yes. One owner confirmed correct indicators and fan operation at 230 V and 400 V after rearranging cams and a middle terminal link. Test both positions after reassembly. [Elektroda, 123zbycho, post #16993070]