Hello. I have read a lot of similar topics and I have already learned a lot about this engine but I still have a problem with my tdi.

Hello.

Pajient Audi a3 8l 130km 1.9dti.

The car stopped pulling from the bottom some time ago (once from around 1800 it was already felt that it was pulling and sometimes from 2800-2900) the diagnosis made by the mechanic was a turbo. He took out and sent to a company that deals with regeneration. He came in and he was supposed to be around 2,000, but after a month he started to fail something, once he does not. Sometimes it pulls up to 3,000, sometimes from 3,000 and sometimes it falls into emergency mode and generally does not pull and then the maximum speed is 120km / h.

At the beginning I cleaned the egr - a noticeable difference on Plus but that was not a problem. Still not pulling. I cut off the flow to see if there would be any difference but it wasn't.

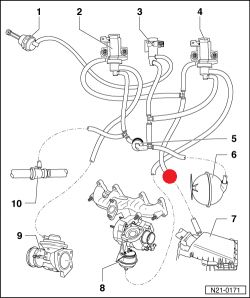

It turned out that there is no vacuum on the turbo. I took off the hose from the vacuum valve, sucked air in my mouth and inserted the screw in the hose - test drive and car regained power.

The first diagnosis is a vacuum valve, but when extinguishing the car, the throttle flap will not vibrate (and while sucking the throttle hose normally goes without any resistance), it is strange for me that both sensors should fail, unless the damper has not worked for a long time and now it has broken from the turbo.

But I had an interface from bmw and it is the same as from vag so I installed the vagcom program and there were two engine errors from the flow but by cutting it off on a trial basis and a second error from overloading the turbo and probably by driving on the screw in the hose.

Errors cleared short test drive and errors not recovered. (But to be sure tomorrow I will connect when I get back from work, maybe it would be a short trip to make a mistake come up again)

Amazingly, there were no errors on the n75 and egr vacuum valves I was betting on.

Further on, I come to the vacum pump. The high vacuum (checked with a finger) draws in strongly and the brakes work properly even when the brake is applied frequently.

And connecting the hose from the vacuum from the turbo to the Tee just behind the vacum pump (bypassing the vacuum valve) the car drives as it should, i.e. pulls from below 2 thousand.

So I bet for this pump is efficient but as I have read I like to loosen the metalwork from the pump and for me it is also loose when I move the hose. But despite this, the turbo turns on and the brakes work

Does anyone have any suggestions ideas what to check? I will add that the pressure hoses checked by the eye seem to be good. Also connected correctly to the valves checked with etk.

Hello.

Pajient Audi a3 8l 130km 1.9dti.

The car stopped pulling from the bottom some time ago (once from around 1800 it was already felt that it was pulling and sometimes from 2800-2900) the diagnosis made by the mechanic was a turbo. He took out and sent to a company that deals with regeneration. He came in and he was supposed to be around 2,000, but after a month he started to fail something, once he does not. Sometimes it pulls up to 3,000, sometimes from 3,000 and sometimes it falls into emergency mode and generally does not pull and then the maximum speed is 120km / h.

At the beginning I cleaned the egr - a noticeable difference on Plus but that was not a problem. Still not pulling. I cut off the flow to see if there would be any difference but it wasn't.

It turned out that there is no vacuum on the turbo. I took off the hose from the vacuum valve, sucked air in my mouth and inserted the screw in the hose - test drive and car regained power.

The first diagnosis is a vacuum valve, but when extinguishing the car, the throttle flap will not vibrate (and while sucking the throttle hose normally goes without any resistance), it is strange for me that both sensors should fail, unless the damper has not worked for a long time and now it has broken from the turbo.

But I had an interface from bmw and it is the same as from vag so I installed the vagcom program and there were two engine errors from the flow but by cutting it off on a trial basis and a second error from overloading the turbo and probably by driving on the screw in the hose.

Errors cleared short test drive and errors not recovered. (But to be sure tomorrow I will connect when I get back from work, maybe it would be a short trip to make a mistake come up again)

Amazingly, there were no errors on the n75 and egr vacuum valves I was betting on.

Further on, I come to the vacum pump. The high vacuum (checked with a finger) draws in strongly and the brakes work properly even when the brake is applied frequently.

And connecting the hose from the vacuum from the turbo to the Tee just behind the vacum pump (bypassing the vacuum valve) the car drives as it should, i.e. pulls from below 2 thousand.

So I bet for this pump is efficient but as I have read I like to loosen the metalwork from the pump and for me it is also loose when I move the hose. But despite this, the turbo turns on and the brakes work

Does anyone have any suggestions ideas what to check? I will add that the pressure hoses checked by the eye seem to be good. Also connected correctly to the valves checked with etk.