Hello, honorable forum members.

Please help. Maybe someone will have an idea for my situation.

I will use specific links, and to be clear, but this is not an advertisement - I note.

I bought a PROEKO PLUS boiler from this link http://www.kotly-witkowski.pl/kotly/proeko-plus

In addition, I bought a supposed to be very good in bags from this link https://ekogroszekprestige.pl/mial-weglowy-pakowany/

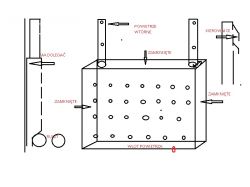

Unfortunately, after some time I realized that this boiler is not 100% fine. It has an airflow only from the ash pan and only on one side. It has no nozzles in the charging chamber. The air from the fan does not pass through the fuel. I light up from above. Proton PID controller.

In connection with the above, I have made a RHS profile with holes drilled from the bottom up. Length is about 0.5m long. Blinded from above. I put it in the middle of the grate. Air is leaking now. On top of the fine coal I put some coal on the fire. It burns like stupid, but when the coal burns out, the dust does not give much heat. Problem with reaching the set temperature. In fact, it barely heats the stove itself (I set the pump to turn off around the set temperature). As if there was too much air (cooling with blowing). As if there were no calories in fuel. You can't see the blue flames.

I am asking for some ideas from experienced smokers. What can I do here. I bought the cauldron for my in-laws. I bought them had and thought that this species would be a rocket, and here my hands drop. I'm in dead end. Boiler 11KW. The manual says that from about 16KW there are nozzles on the back wall of the hearth. I didn't know about it. I'm in a bind of what to do. I've never smoked. I am asking for some help. Thank you in advance.

Please help. Maybe someone will have an idea for my situation.

I will use specific links, and to be clear, but this is not an advertisement - I note.

I bought a PROEKO PLUS boiler from this link http://www.kotly-witkowski.pl/kotly/proeko-plus

In addition, I bought a supposed to be very good in bags from this link https://ekogroszekprestige.pl/mial-weglowy-pakowany/

Unfortunately, after some time I realized that this boiler is not 100% fine. It has an airflow only from the ash pan and only on one side. It has no nozzles in the charging chamber. The air from the fan does not pass through the fuel. I light up from above. Proton PID controller.

In connection with the above, I have made a RHS profile with holes drilled from the bottom up. Length is about 0.5m long. Blinded from above. I put it in the middle of the grate. Air is leaking now. On top of the fine coal I put some coal on the fire. It burns like stupid, but when the coal burns out, the dust does not give much heat. Problem with reaching the set temperature. In fact, it barely heats the stove itself (I set the pump to turn off around the set temperature). As if there was too much air (cooling with blowing). As if there were no calories in fuel. You can't see the blue flames.

I am asking for some ideas from experienced smokers. What can I do here. I bought the cauldron for my in-laws. I bought them had and thought that this species would be a rocket, and here my hands drop. I'm in dead end. Boiler 11KW. The manual says that from about 16KW there are nozzles on the back wall of the hearth. I didn't know about it. I'm in a bind of what to do. I've never smoked. I am asking for some help. Thank you in advance.