Hello.

I am asking fellow installers for professional advice.

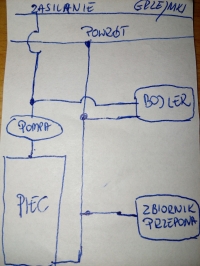

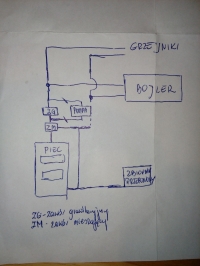

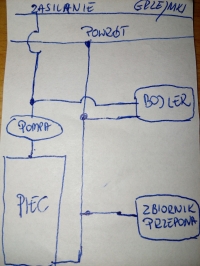

On the "drawing" below I have posted the current existing heating installation in the apartment.

The furnace that was used is a butterbur furnace.

Currently, an eco-pea coal furnace with a screw feeder is ordered.

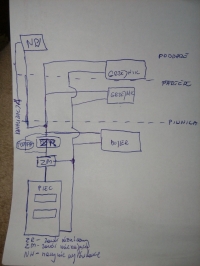

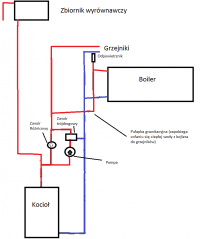

Namely, I am talking about the modification of this installation to mount a mixing valve so that the water in the furnace at the return temperature is higher.

1. Where should the mixing valve be installed (definitely before the pump)?

2. Use a 3-, 4-way valve?

3. Where is the best place to install safety valves (currently one on the supply, the other on the return directly at the entrance to the furnace)?

4. I understand that the 4-way valve gives us the ability to control the radiator temperature and raise the temperature at the return of the furnace (whether I'm wrong

I mention that the installation is "closed" has a diaphragm tank.

I am asking for professional advice not to make an assembly error

I am asking fellow installers for professional advice.

On the "drawing" below I have posted the current existing heating installation in the apartment.

The furnace that was used is a butterbur furnace.

Currently, an eco-pea coal furnace with a screw feeder is ordered.

Namely, I am talking about the modification of this installation to mount a mixing valve so that the water in the furnace at the return temperature is higher.

1. Where should the mixing valve be installed (definitely before the pump)?

2. Use a 3-, 4-way valve?

3. Where is the best place to install safety valves (currently one on the supply, the other on the return directly at the entrance to the furnace)?

4. I understand that the 4-way valve gives us the ability to control the radiator temperature and raise the temperature at the return of the furnace (whether I'm wrong

I mention that the installation is "closed" has a diaphragm tank.

I am asking for professional advice not to make an assembly error