Hi,

I note right away that I am still learning, so please be understanding. The questions are as follows:

1) How best to perform the PEN to PE and N split point in a TN-C installation. I've seen 3 "schools" in general, all of them lead to the same but different way of connection:

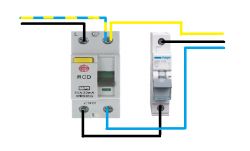

A) On the RCD terminal, I understand that it only makes sense in the case of small switchgears / short cables, when the cables from the meter to the switchgear are not replaced, and it makes sense with a maximum of 1 RCD.

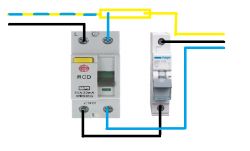

B) On the PE bridge, this seems to make the most sense with small substations.

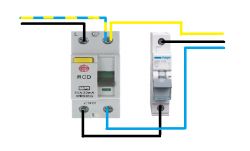

C) The division into a separate bridge N1 and N2, it probably only makes sense with larger switchgears and a few RCDs, because most of the "home" ones have only 2 bridges for PE and N installed at the factory.

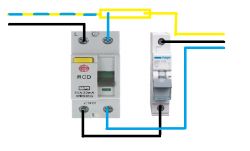

2) As you deal with too long jumper rails, it seems most sensible to pull the copper out of the plastic sheath, break the tooth under the N in the RCD, cut the copper after the last tooth connected, cut the plastic a little further so that it is not possible to touch the live metal and put it back on .

3) What is the best option for joining aluminum with copper (for cases A, B, C) because it often happens that someone has aluminum meter wires, which for some reason cannot / will not be replaced.

I note right away that I am still learning, so please be understanding. The questions are as follows:

1) How best to perform the PEN to PE and N split point in a TN-C installation. I've seen 3 "schools" in general, all of them lead to the same but different way of connection:

A) On the RCD terminal, I understand that it only makes sense in the case of small switchgears / short cables, when the cables from the meter to the switchgear are not replaced, and it makes sense with a maximum of 1 RCD.

B) On the PE bridge, this seems to make the most sense with small substations.

C) The division into a separate bridge N1 and N2, it probably only makes sense with larger switchgears and a few RCDs, because most of the "home" ones have only 2 bridges for PE and N installed at the factory.

2) As you deal with too long jumper rails, it seems most sensible to pull the copper out of the plastic sheath, break the tooth under the N in the RCD, cut the copper after the last tooth connected, cut the plastic a little further so that it is not possible to touch the live metal and put it back on .

3) What is the best option for joining aluminum with copper (for cases A, B, C) because it often happens that someone has aluminum meter wires, which for some reason cannot / will not be replaced.