Hello. There is a case that the kitchen was renovated in the apartment. I do not have a gas license, so the client called the administration regarding the shortening of the gas pipe. The administration accepted the order, sent a man, informs about the cost per job. And the man refuses to do it. Reports that the job is not feasible. Personally, I want to do it after hours, but I will not issue a certificate that everything is ok. Gas is general and each tenant's consumption is included in the rent, so no one except the administration can come and do it.

This is a description of the situation that is taking place. Monopoly.

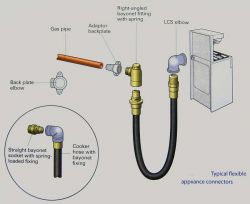

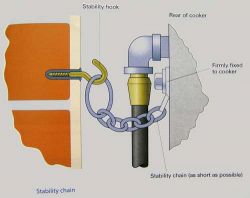

And now maybe someone is more familiar with and knows what are the modern safety regulations related to gas installations?

Somewhere my ears crossed my mind that there should be no elbow or muff connections in front of the valve. Maybe it can be done by the administration free of charge under the security regulations?

This is a description of the situation that is taking place. Monopoly.

And now maybe someone is more familiar with and knows what are the modern safety regulations related to gas installations?

Somewhere my ears crossed my mind that there should be no elbow or muff connections in front of the valve. Maybe it can be done by the administration free of charge under the security regulations?