unitral wrote: Since he wasn't doing the pressure test, he wasn't doing it at all.

Such an installation should not be commissioned and approved, and a protocol is issued after the pressure test.

Exactly. Yesterday, the administrator turned off the gas installation completely (+ protocol) and presented the relevant regulations, which show that in the case of moving the stove from the bathroom to the kitchen, a project is required (unfortunately, I will not skip that, on the other hand I want everything to be "lege artis"). The stove has to be moved because the cubature of the bathroom is smaller than 8 m3. After collecting a few necessary documents, I will commission a project - how much does it cost? maybe you have orientation. I will send an appropriate letter to the contractor to comment on the situation and ask for authorization.

Added after 8 [minutes]: unitral wrote: You can plaster your welded steel pipes, just make a plan (handwritten and attach it to your apartment papers) if any changes are needed in the future ...

Exactly. Yesterday in the technical department I received information that it is practically not used to lay steel pipes welded under the plaster because each plastering mortar causes corrosion of these pipes (lime or other component). However, I would really like to cover these pipes (or rather my girls), which assume that the stove itself disfigures the kitchen. Maybe you have experience in this field?

After this installation is done, I can take photos and additionally a sketch. I think that laying such a pipe under the plaster on the wall, where the ventilation ducts are, will not be a problem anymore?

Added after 6 [minutes]: On the bill it says: assembly of the bathroom stove along with the material. On the protocol:

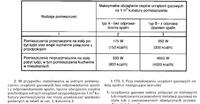

Reg. MIn Internal Sp. of August 16, 1999 on the technical conditions of use of residential buildings, item 836

Installation tested for tightness with compressed air under pressure

1 /. 0.05 MPA for 30 minutes

2 /. 5kPa for gas meters with gas appliances for 15 minutes.

It is found that the test did not show a pressure drop