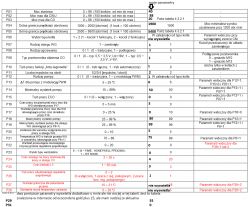

Ajronix wrote: As for the P24 parameter, the run-on time at the starting power for operation in the central heating circuit is 4 seconds. Can I change it to 2-3 seconds without or not much?

You can, or even must, check whether this will change anything in the boiler's operating culture.

Ajronix wrote: I wonder about parameter 1 - it is as high as 40. But to reduce it, an exhaust gas analysis is necessary?

an exhaust gas analyzer is not needed for take-off power.

According to the instructions, P01=25, so I would change it to 25 for testing.

If the boiler starts up explosively, raise the P01 parameter.

Water heating in the boiler depends on, among others: from the water flow through the boiler.

To increase the water flow, you need to increase the efficiency of the pump.

Set P14 and P18 to 99, this should force the pump to operate at constant 100% capacity.

Do a test with these parameters and write how it will change the boiler's operating characteristics, i.e. after how long will the burner go out?

If this does not cause the boiler to run continuously, I would be inclined to think that your installation is screwed up.

You can further try to increase the P20 hysteresis to increase the burner shutdown threshold.

If you set the hysteresis to 10, at the set 29 degrees, the burner will turn off at 39. Maybe this is enough for the water temperature in the boiler to drop and stabilize.