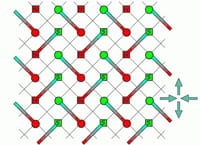

Hi,First, I am not an electrical engineer. I was an electrician back in the 80's and these days I'm a software engineer, so I have only a basic knowledge with lots of large gaps in it, at least compared to most of you on these forums. I have an idea that is probably crazy but I wanted to run it past people who might be able to work out whether or not it is worth pursuing.The idea is for a semi-flexible electromagnetic muscle that can actuate in either push or pull directions. Useful, I think, for robotics. It is similar in some ways to existing pneumatic muscles which use an inner rubber tube that can be inflated, with a cloth outer shell in a lattice weave (like a shoelace) that limits the expansion - when the tube is inflated the radius increases but the length decreases, so the "muscle" contracts. If you don't know what I'm talking about there are plenty of videos of pneumatic muscles on youtube.My idea is to take the physical principle of that that lattice weaved cloth, but build it out of a weave of many, small electromagnets - I mean just enamelled copper wound around small nails.Using the pattern of diamond plate metal flooring - imagine each bump is a small electromagnet connected end to end into lines and hinged where the lines cross like an accordion lattice, but wrapped into a cylinder. The magnets are also wired end to end in series.You have two orientations of electromagnets - say clockwise and counter clockwise around the cylinder, set at 45 degrees to the run of the cylinder, and 90 degrees to each other on each hinge join. If both orientations are wired with positive DC voltage at the same end, it forms a pattern of like poles running the length of the cylinder, and rings of opposing poles around the cylinder, which in theory should squeeze the rings together and push apart along the lines, making the lattice extend along its length. If you invert only one of the orientations then the pattern reverses - rings of like poles and lines of opposing poles, causing it to fatten and contract.Since one orientation of magnets never changes, I think it may be possible to replace those with rare earth magnets.That is the basic idea, I think the smaller the magnets are the better, since magnetic force falls off so quickly. But there are so many things I don't know that I would not be surprised if there are reasons this would not work at all, let alone how power efficient it would be compared to a couple of solenoids. Then there a ton of other questions if it is actually viable - to maximise efficiency, what length of iron core, what gauge of wire, how many turns per core, how far apart to place them etc. Anyway, what do people here think? Completely misguided? Worth trying to make a prototype? At this point I'm not even sure whether or not actually requires rigid connections between the cores, I suspect the first prototype could be made from nails and wire held together with fishing line and hot glue...