Sorry, but after reading some other topics of this forum in the meantime, I found out some interesting things for me and changed a bit of my previous post without noticing that on the other side there was already an answer to it and there was confusion with the order of numbers.

bandzior2 wrote:

The earthing goes from the transformer on the poles. Every few poles goes down to the ground.

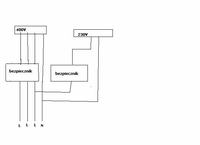

Because the 2 extra cables are (neutral and ground). They fulfill a protective function. If the device is in the field and is earthed, e.g. a metal device with a metal table to the ground, it is not necessary to connect the earthing cable.

So, can I release the mass of the device into the soil?

The mass is known what it is for - and what is ZERO for and where does it run (power plant, nearest transformer or soil)?

What about the rest of my questions:

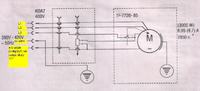

1. According to the previously drawn star diagram, is it a 230V 3-phase motor? I am asking for this because in the same store there is a 220V saw with the same design, power and price as my 400V.

2. Is the 230V 3000W motor weaker than 400V 3000W?

3. I found one topic on this forum where it says that you can bridge 0 with mass, but only in one case. Unfortunately, it is a bit unclear in this thread and I cannot understand if it can be done in a 4-wire device to fit a 5-wire installation or vice versa - i.e. in a 4-wire installation to match it to a 5-wire device.

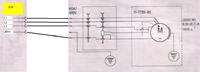

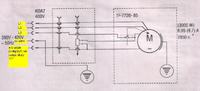

More and more my doubts are resolved and if it goes on at such a pace, today or tomorrow I will start a new equipment, i.e. the Dedra 7727 circular saw. I enclose a diagram of its connection with 4 decoded cables and a question about the fifth-last cable. I know that the saw has a thermal switch and two buttons 1 and 0.

Unfortunately, the factory did not give any description for it, and in particular did not explain how to connect the saw to a 3-wire or 4-wire network.