As for the drive ...

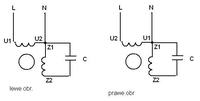

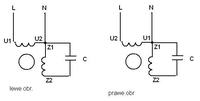

Motors, or rather windings of single-phase motors, it is known in advance that the shift angle between the main and (auxiliary, starting) is 90 degrees.

In short, so as not to confuse your minds:

1. Symmetrical two-phase windings (where there is only and only starting with a centrifugal or "overcurrent" switch); they play the role of the starting winding (it is turned on during the start-up)

2. asymmetric two-phase winding, where there is a capacitor in p. Not only is it involved in the start-up process, but you might want to amplify the moment.

Coming back to the point.

When choosing a condenser and its parameters ... its capacity, or rather the voltage, is less important.

If the condenser capacity is too small, the motor will only have a low torque.

On the other hand, if you put the capacitor on too low voltage (e.g. 230-250V), you will overheat the auxiliary windings during longer operation.

I suggest a capacitor with the parameters:

approx. 10 uF / 400V

second, if I'm not mistaken. According to of the energy law, 1-f asynchronous motors that can be connected to the public grid must not exceed 1.5kW, therefore they are not produced for higher powers.

Added after 23 [minutes]: Yes, I did not specify that the capacitor between 14-20uF should meet the expectations, it costs about PLN 20.

However, when it comes to changing the direction of rotation, it is enough to change the direction of the current flow in one of the windings.