Hello

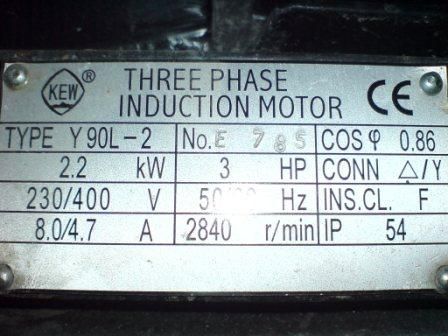

I recently purchased an electric motor powered by 230V / 380V and I want to connect it to 230V. The engine power is 2.2kW.

With the help of the forum, I calculated that I would need a 132-154 uF capacitor for start-up

I also found a connection diagram with both the starting capacitor and the operation (but to a different motor), according to one diagram with disconnection of the starting capacitor, I would like to make such a switch.

But the most important thing is because I do not know what capacitor to use, what capacity it should be.

Can someone help me calculate its capacity.

Below I enclose diagrams:

I recently purchased an electric motor powered by 230V / 380V and I want to connect it to 230V. The engine power is 2.2kW.

With the help of the forum, I calculated that I would need a 132-154 uF capacitor for start-up

I also found a connection diagram with both the starting capacitor and the operation (but to a different motor), according to one diagram with disconnection of the starting capacitor, I would like to make such a switch.

But the most important thing is because I do not know what capacitor to use, what capacity it should be.

Can someone help me calculate its capacity.

Below I enclose diagrams: