I have a boiler as in the topic = Viessmann Vidtodens 100-W (9-26kW) with the following problem ....

The display shows the error F4, which means according to the service manual:

The stove behaves as follows:

1) After switching on, the stove tries to start the burner - you hear a running fan and the firing electrode, and you can see gas intake on the home gas meter. I know that the electrode is sparking, because I started the boiler with the igniter in my hand and you can see that it is sparking (of course the gas was turned off).

2) Once every 10-15 attempts, the boiler fires up, but this firing up takes quite a long time. Normally, it takes about 0.5-1 seconds to ignite the flame, and in my case it takes about 2-3 seconds. This is how long you can hear the sparking of the fuse and an attempt to ignite it. Additionally, the ignition itself takes place in two stages - that is, you can hear two separate gas explosions

3) And here the puzzle begins, because sometimes the boiler ignites in this 3 second, it literally goes out after a while (in the fourth second) and the fan reduces its speed again to repeat the attempt to start the ignition

4) In most cases, the boiler repeats the ignition attempt, probably 5 times, and if it does not ignite even once, it causes error F4. When ignition occurs (temporary for about 1 second), the boiler falls into a loop of attempts to ignite.

What I did to improve it were the activities described in the service manual from pages 24 to 29, so:

- I dismantled the entire burner, dismantled it completely and cleaned it

- I cleaned the heating surfaces of the stove (vacuuming + brushing the surface and rinsing with plenty of water)

- I cleaned the entire air supply duct (from the Wenturi duct, through the fan to the radiator)

- I cleaned the condensate drain

- I cleaned the ignition electrode at the sparking point with 320 grit sandpaper and tried several different electrode gap settings

- I reset the boiler according to page 36 of the manual

- Additionally, I cleaned the gas filter before entering the stove.

- I checked that the voltage to the boiler was supplied according to the requirements - i.e. phase to L1 connector, Neutral to N, and ground to ground.

The boiler is powered by propane gas from a cylinder.

The 2700l cylinder has a first stage reducer with a range of 0-3 bar, whose manometer (possibly damaged) shows about 4.5 bar.

Then I have a second stage reducer reducing to 37mbar, which has visible traces of sticky deposit in the area of the relief valve.

This whole thing raises the following questions for me:

1) Why does the boiler have ignition problems (it works for about half a year, but after the warranty)?

2) What causes the problem with the flame retention and that the boiler goes out right after ignition?

3) If the 2nd stage reducer gives a pressure other than 37mbar, can the boiler have problems with keeping the flame and igniting the flame itself?

4) What do you propose to start in this situation - from the boiler review (assumingthat the inlet pressure is correct), or from the replacement of the 1-stage reducer on the cylinder and the pressure control after the 2nd reducer?

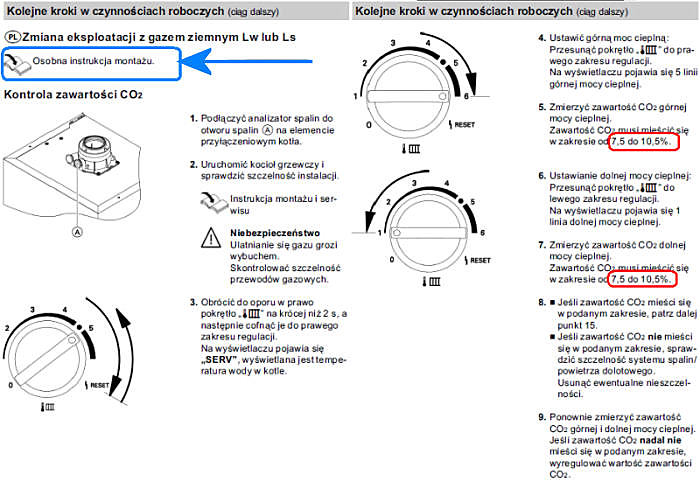

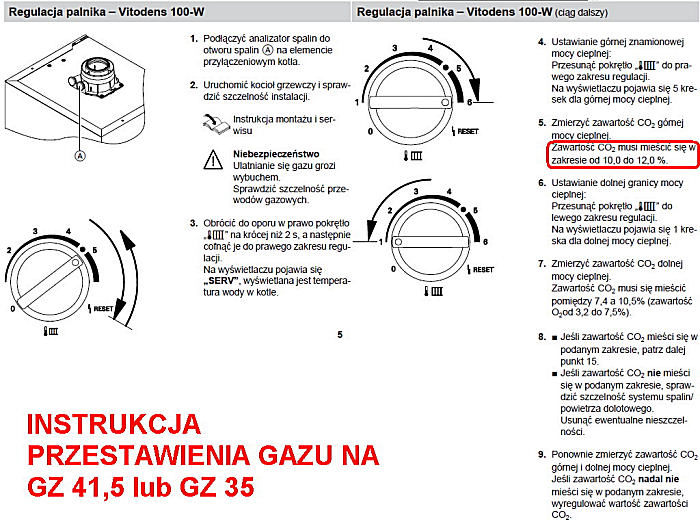

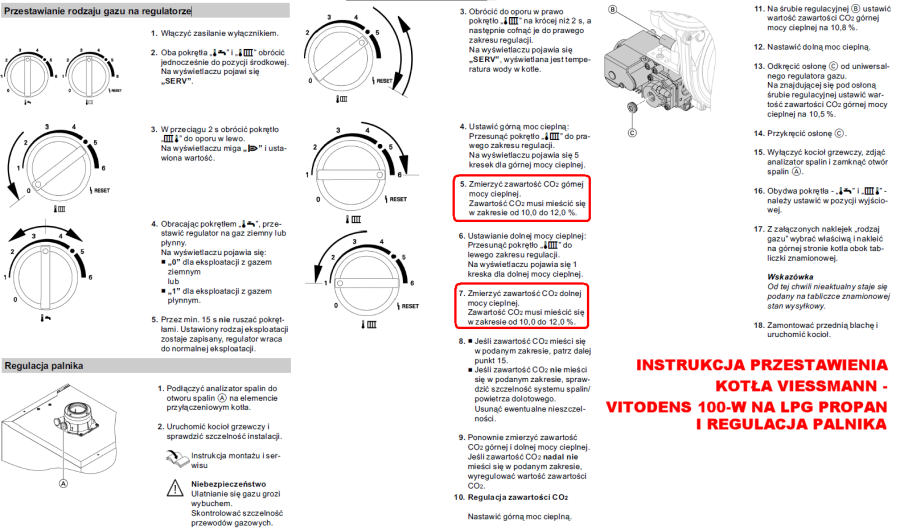

5) Can the problems with the flame and ignition be influenced by bad composition of exhaust gases, residual CO2 value?

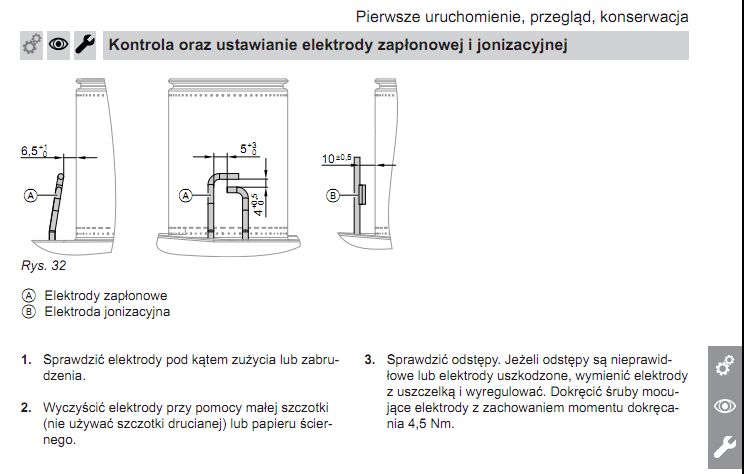

6) The service manual presents the ignition electrode as a wear-out element, but I do not understand what can wear out if there are only two appropriately shaped wires? Can cleaning the electrode with sandpaper damage it in any way? Below is a photo of my electrode after cleaning with sandpaper.

I enclose the assembly and service instructions:

https://www.elektroda.pl/rtvforum/files-rtvfo...t_a_viessmann_-_model_vitodens_100-w_1744.pdf

The display shows the error F4, which means according to the service manual:

The stove behaves as follows:

1) After switching on, the stove tries to start the burner - you hear a running fan and the firing electrode, and you can see gas intake on the home gas meter. I know that the electrode is sparking, because I started the boiler with the igniter in my hand and you can see that it is sparking (of course the gas was turned off).

2) Once every 10-15 attempts, the boiler fires up, but this firing up takes quite a long time. Normally, it takes about 0.5-1 seconds to ignite the flame, and in my case it takes about 2-3 seconds. This is how long you can hear the sparking of the fuse and an attempt to ignite it. Additionally, the ignition itself takes place in two stages - that is, you can hear two separate gas explosions

3) And here the puzzle begins, because sometimes the boiler ignites in this 3 second, it literally goes out after a while (in the fourth second) and the fan reduces its speed again to repeat the attempt to start the ignition

4) In most cases, the boiler repeats the ignition attempt, probably 5 times, and if it does not ignite even once, it causes error F4. When ignition occurs (temporary for about 1 second), the boiler falls into a loop of attempts to ignite.

What I did to improve it were the activities described in the service manual from pages 24 to 29, so:

- I dismantled the entire burner, dismantled it completely and cleaned it

- I cleaned the heating surfaces of the stove (vacuuming + brushing the surface and rinsing with plenty of water)

- I cleaned the entire air supply duct (from the Wenturi duct, through the fan to the radiator)

- I cleaned the condensate drain

- I cleaned the ignition electrode at the sparking point with 320 grit sandpaper and tried several different electrode gap settings

- I reset the boiler according to page 36 of the manual

- Additionally, I cleaned the gas filter before entering the stove.

- I checked that the voltage to the boiler was supplied according to the requirements - i.e. phase to L1 connector, Neutral to N, and ground to ground.

The boiler is powered by propane gas from a cylinder.

The 2700l cylinder has a first stage reducer with a range of 0-3 bar, whose manometer (possibly damaged) shows about 4.5 bar.

Then I have a second stage reducer reducing to 37mbar, which has visible traces of sticky deposit in the area of the relief valve.

This whole thing raises the following questions for me:

1) Why does the boiler have ignition problems (it works for about half a year, but after the warranty)?

2) What causes the problem with the flame retention and that the boiler goes out right after ignition?

3) If the 2nd stage reducer gives a pressure other than 37mbar, can the boiler have problems with keeping the flame and igniting the flame itself?

4) What do you propose to start in this situation - from the boiler review (assumingthat the inlet pressure is correct), or from the replacement of the 1-stage reducer on the cylinder and the pressure control after the 2nd reducer?

5) Can the problems with the flame and ignition be influenced by bad composition of exhaust gases, residual CO2 value?

6) The service manual presents the ignition electrode as a wear-out element, but I do not understand what can wear out if there are only two appropriately shaped wires? Can cleaning the electrode with sandpaper damage it in any way? Below is a photo of my electrode after cleaning with sandpaper.

I enclose the assembly and service instructions:

https://www.elektroda.pl/rtvforum/files-rtvfo...t_a_viessmann_-_model_vitodens_100-w_1744.pdf