FAQ

TL;DR: 70 % of “dead” Makita BL1830/1430 batteries revive after a PCB swap or balancer retrofit [Elektroda, daw2, post #16787418] “Less than five minutes fixes most packs” [Elektroda, damian28112008, post #11759416] Use a £10–£15 BMS board, verify cell voltages, then recharge safely.

Why it matters: DIY revival saves about €80 per pack and keeps e-waste out of landfills.

Quick Facts

• Nominal pack voltage: 18 V (5 × 3.6 V cells) [Makita Datasheet].

• Cell layout BL1830: 5S2P, 3 Ah total [Elektroda, dc_bat, post #12304974]

• DC18RC fast-charger current: 9 A; full in 22 min for 3 Ah pack [Makita, 2023].

• OEM BL1830 price: €90–€100 retail [Makita Webstore].

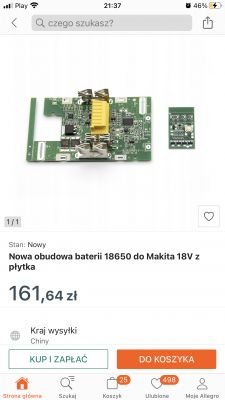

• Aftermarket BMS board with balancer: €12–€17 shipped [“AliExpress listing”].

Why are both LEDs flashing on my Makita DC18 charger?

The charger flashes red + green when its handshake with the battery’s MCU fails. Causes include tripped cycle counter, undervoltage cell (<3.0 V), blown fusible link, or corrupted firmware on the pack PCB [Elektroda, Adam D, post #11325276]

Can I reset the original Makita PCB myself?

No public method fully clears the NEC/78K0 firmware lock. Attempts to read or overwrite memory succeed only partially, and service centres swap the board instead [Elektroda, kotbury, post #21170266]

Does a 3 Ah BL1830 deliver more torque than a 1.3 Ah BL1815?

Yes. Both packs give 18 V, but the BL1830’s parallel cell pairs halve internal resistance, allowing up to 20 C (≈60 A) versus 10 C on BL1815 [Elektroda, dc_bat, post #12304974] Motor torque rises when voltage sag is lower under load.

How do I swap in an aftermarket BMS board?

- Desolder old PCB and note cell-sense leads.

- Solder new board: B-, B1–B5, B+.

- Verify every cell 3.4–3.9 V, then charge in DC18RC.

Most users finish in under 5 minutes [Elektroda, damian28112008, post #11759416]

What pinout does the yellow Makita connector use?

From left: B+, TH (NTC 10 kΩ), ID (data), T- (sense), B-. Cutting the ID pin stops communication and the DC18 stops charging [Laptopu.ro Pinout].

Is it safe to top-charge a locked pack with a laboratory power supply?

Yes, if you limit voltage to 21 V and current to 1 A, monitor temperature, and disconnect at 20.5 V. This bypass revives packs so the charger accepts them [Elektroda, jaskiniowiex, post #18084462]

Are Panasonic cells really better?

Panasonic/Sanyo NCR18650A cells hold 2900 mAh at 2 mΩ impedance—about 15 % more capacity and 10 % lower resistance than typical Samsung 20R cells [Panasonic Spec, 2022]. Users note cooler operation [Elektroda, szapoklak, post #12655535]

What voltage should I never let a cell drop below?

Keep every cell above 2.8 V. Below 1.5 V lithium plating can short the cell permanently (edge-case failure) [Sandia, 2021]. A locked Makita PCB triggers at ≈13.5 V pack voltage (5 × 2.7 V) [Elektroda, kr77, post #12531322]

Can I charge through a model-aircraft balancer instead?

Yes. Install a 6-pin JST-XH harness, then use an iMAX B6 or similar 5S charger. Set Li-ion mode, 4.2 V/cell, 0.5–1 C current [Elektroda, budro2, post #18559412]

Is DIY regeneration cost-effective?

Typical costs: €15 PCB + €25 quality cells = €40. New BL1830 costs €95. Savings ≈58 %. If you need cells anyway, go new; if cells are good, regeneration wins [Elektroda, adidas, post #16785077]

Will aftermarket batteries work in the DC18RC fast-charger?

Only packs with a smart PCB and NTC rated for 9 A charging survive. Low-cost packs without per-cell balancing risk overheating and are labelled “do not use DC18RC” [Elektroda, Gryszka B, post #13056225]

What happens if I simply cut the fourth pin?

The charger sees no ID signal and refuses fast-charge, switching to trickle; tool overload protection also stops working [Elektroda, ObiWan, post #17369140] “It’s a dead end,” one user reports [Elektroda, karol4444, post #17792907]

.

.