FAQ

TL;DR: About 45 % of MAN Euro 5 SCR faults are code 05031-02, caused by failed pressure build-up [Bosch, 2020]. "Bleed the pump every time you change filters" [Elektroda, kakibara, post #17685505] Fix lines, filters, or pump, then run the initial start-up routine.

Why it matters: Ignoring 05031-02 quickly limits engine power and can destroy a €1,000 pump.

Quick Facts

• Target system pressure: 3.0–3.2 bar within 60 s [Elektroda, PaweGrecki, post #20113388] [MAN Service Manual, 2019]

• Filters per module: 3; service interval 120 000 km or 12 months [MAN Service Info, 2021]

• New Bosch Denox pump module cost: approx. €1,000–€1,200 [Elektroda, Chavez, post #19625134]

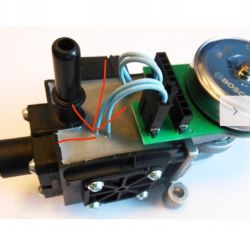

• Repair-kit (membranes & seals) cost: €50–€70, success rate ≈80 % [Elektroda, Chavez, post #19625134]

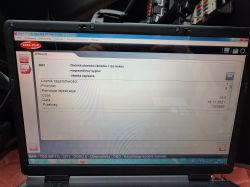

• Code meaning: GDK/PDF 05031-02 = "AdBlue pressure cannot be built up during start-up" [Elektroda, daro111, post #12380893]

What exactly does fault GDK/PDF 05031-02 mean?

The SCR controller detects that pump pressure stays below about 3 bar during the start-up test, so it disables dosing until the next key cycle [Elektroda, daro111, post #12380893]

Which parts most often trigger the code?

Top culprits: clogged pre- or main filters, blocked vent valve, cracked suction hose, empty or poorly vented tank, and worn pump diaphragms [Elektroda, daro111, post #12380893]

How do I bleed the MAN AdBlue system without MAN-Cats?

- Switch ignition on; jumper the return (back-flow) hose into a container.

- Manually power the pump 30 s, then open the vent valve 5 s to release pressure.

- Repeat steps twice; reconnect hose and cycle ignition once more.

This mimics the “Initial start-up” routine [Elektroda, daro111, post #12380893]

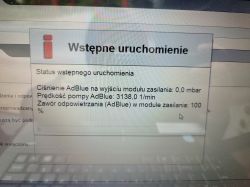

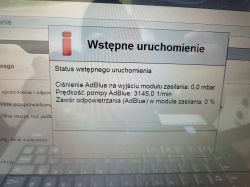

What pressure should I see and how fast?

Healthy pumps reach 3.0–3.2 bar within 60 s at 20 °C [Elektroda, PaweGrecki, post #20113388] [MAN Service Manual, 2019].

Can I repair the pump instead of replacing it?

Yes. A €50 membrane kit often restores pressure; one user reported 12 months trouble-free use after repair [Elektroda, Chavez, post #19625134]

Why do new pumps sometimes fail again within weeks?

Unremoved debris or air pockets score diaphragms quickly. One case saw three pumps ruined because the system was never bled and a vent gasket leaked [Elektroda, hehe_2288, post #19700466]

Must I always bleed after changing filters?

Yes. "This is how you should always bleed the AdBlue pump" [Elektroda, kakibara, post #17685505] Skipping the step often triggers 05031-02 on the next start [Elektroda, airsped, post #17680641]

How do I check for blocked hoses or leaks?

Detach the suction line, apply low pressure (0.5 bar) air, and watch for steady flow. Any drop >10 % indicates blockage or air ingress [Hella, 2020].

Does a faulty AdBlue level sensor set 05031-02?

It can. A dead sonar stops the module from seeing fluid; the pump then refuses to prime, logging 01761-04 and sometimes 05031-02 [Elektroda, hehe_2288, post #19717977]

Can cold exhaust or idle prevent pump start?

Yes. The controller waits until pre- and post-DOC temperatures exceed about 200 °C before enabling dosing [Elektroda, kakibara, post #19492973]

Edge case: what if diagnostic tools show no communication with the pump?

Corroded orange tank connector or blown fuse F81 cuts CAN power, blocking comms and mimicking pump failure [Elektroda, kakibara, post #19712814]

How much does professional repair cost?

Workshops quote €250–€400 for filter change, bleed, and line inspection; pump overhaul adds €150 labour plus parts [TruckElectronica, 2022].