Hello,

I do not know if I am asking this question in a good department.

Maybe some of you will advise me on how to cut the thread of a small screw so that it can be screwed in later.

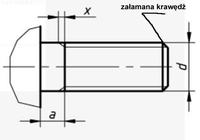

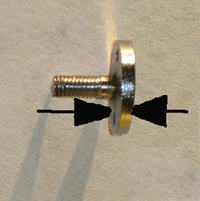

The screw is small in size:

Head diameter 12mm

Thread length 16mm

Thread diameter approx. 2mm

If anyone has tools to cut professionally 3 pcs of such screws for a fee, please contact me too.

thanks in advance for your answer

I do not know if I am asking this question in a good department.

Maybe some of you will advise me on how to cut the thread of a small screw so that it can be screwed in later.

The screw is small in size:

Head diameter 12mm

Thread length 16mm

Thread diameter approx. 2mm

If anyone has tools to cut professionally 3 pcs of such screws for a fee, please contact me too.

thanks in advance for your answer