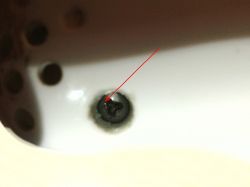

misiek1111 wrote: knock it off by hitting it with a hammer through a flathead screwdriver in this place:

misiek1111 wrote: you could also cut the head with a diax and then unscrew it with a flat screwdriver.

Manipulant5 wrote: The easiest way to grind something like this is a piece of steel rod

Maybe smash the whole thing right away with an ax? Gentlemen ... please - either of these "methods" can be applied to a screw that cannot be unscrewed in any CIVILIZED way; and such (and in addition not destructive and technically correct) is the use of an appropriate tip.

Working several dozen years in the service, I saw the screw heads sufficiently using such "crude" (not to be confused with simple) methods. I omit the aesthetic issues of a damaged screw head, sometimes it is a problem to unscrew the screw at all - because the damaged cuts do not even fit the dedicated tip.

This is why newer and newer cuts of screw heads are invented, to prevent access to the interior by a layman or other "handyman" - or he will resign and return the equipment to the service (cheaper) or he will try, cut the screws, and in the end the equipment will hit to the service = but the repair will be more expensive, because it will be immediately clear that "Ours were here", and no service technician likes to look for what a layman has messed with.

Either use the tools for their intended purpose or trust the service ...