Hello

If the forum misplaced then I apologize and ask the admin to put the topic in the appropriate section.

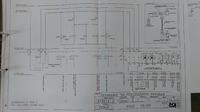

In the Merlo loader died electronic controller that controls the electrovalves in the hydraulic pump. To begin with, a diagram of the conversion :

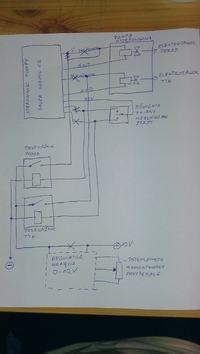

In the original version, the regulated voltage from the controller smoothly controlled the movement of the valves so that the loader does not move rapidly but slowly depending on the value of the potentiometer located near the pedal. This is important especially during charging - it pulls up slowly and not abruptly.

I replaced the controller with two relays that switch 12V to the valves depending on the setting of the direction lever. The relays are switched by shorting the minus to the case near the pedal (instead of the factory potentiometer).

Everything works beautifully only that the charger starts violently. So I came up with an ego solenoid for the solenoid valves. I will place the regulator potentiometer at the pedal.

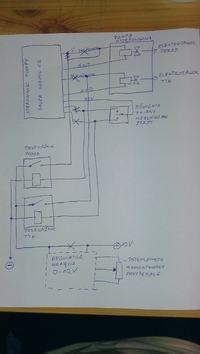

And here a request to you esteemed forumers to give me some scheme of the regulator that will work best here.

The maximum voltage that will flow into the regulator is 14.4 volts, the minimum voltage probably does not have to be 0 or 1 because I do not believe that 1volt will move the solenoid valve enough to get the charger going. As for the control current, it is quite high and measurements showed that it was 19-20A at times. Also a higher power regulator is needed. Thanks in advance for your answers....

If the forum misplaced then I apologize and ask the admin to put the topic in the appropriate section.

In the Merlo loader died electronic controller that controls the electrovalves in the hydraulic pump. To begin with, a diagram of the conversion :

In the original version, the regulated voltage from the controller smoothly controlled the movement of the valves so that the loader does not move rapidly but slowly depending on the value of the potentiometer located near the pedal. This is important especially during charging - it pulls up slowly and not abruptly.

I replaced the controller with two relays that switch 12V to the valves depending on the setting of the direction lever. The relays are switched by shorting the minus to the case near the pedal (instead of the factory potentiometer).

Everything works beautifully only that the charger starts violently. So I came up with an ego solenoid for the solenoid valves. I will place the regulator potentiometer at the pedal.

And here a request to you esteemed forumers to give me some scheme of the regulator that will work best here.

The maximum voltage that will flow into the regulator is 14.4 volts, the minimum voltage probably does not have to be 0 or 1 because I do not believe that 1volt will move the solenoid valve enough to get the charger going. As for the control current, it is quite high and measurements showed that it was 19-20A at times. Also a higher power regulator is needed. Thanks in advance for your answers....