Hello. In the newly built house, we have installed underfloor heating in its entirety, i.e. about 250m2. And so the bottom is served by one 7 circuit divider and the top two 4 and 6 circuit dividers.

The entire heating system is based on a 16 pipe and a total length of approximately 1600m.

The main power supply is an air-water pump which loads the 1000/200 multivalent tank (i.e. 800 liters of CO and 200 DHW) to about 43 degrees Celsius.

In addition, a fireplace with a 24KW water jacket is connected to the container, used occasionally so far.

The floor is powered from the upper part of the buffer through steel pipes (clamping system), the pump is controlled so that it does not pump the coolant cooler than 35 degrees into the floor.

And so, start from the buffer pipe 1 inch, then the thermostatic mixing valve atm341 (protecting against loading too hot medium heated by the fireplace into the floor - the indicator is open to the maximum at 6)) then the pump Wilo Yanos pico 25 / 1-6- (ROW) and then ZZ, then parallel to all three dividers, i.e. one 7-point at the bottom and two 4-point and 6-point on the first floor daw at the top, separated by a tee for 3/4 pipes.

At the moment, the heating is able to maintain the set temperature of about 21 degrees above, while the temperature at the bottom is much higher because the whole is lined with tiles, while the top heats up with more difficulty (most are panels but tiles also in the corridor, bathroom and utility rooms.)

At the moment, the indicators on rotameters oscillate between 0-0.5 and not on all loops. When trying to regulate, i.e. checking the flow on individual beams, after tightening all loops and leaving one (each in turn) on the rotameter, the maximum flow of 2.5-3l / min is displayed. range, but it is known that the pressure in the water supply was greater)

When two manifolds on the third are blocked, the rotameters show the flow in the limit of 1.5.

There is no way I am now able to adjust the flow on the individual loops.

The loops mostly consist of sections of 80 to 100 m, except for 4 shorter ones, between 30-50 meters.

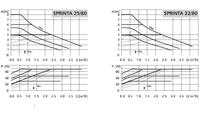

My question is whether the lack of flow is caused by the installation of only one circulation pump for such a large installation, or is it too weak.

What solutions do you recommend?

1.assembly of one more powerful pump - what kind?

2. adding a second pump to supply the attic separately?

3. ???????

The entire heating system is based on a 16 pipe and a total length of approximately 1600m.

The main power supply is an air-water pump which loads the 1000/200 multivalent tank (i.e. 800 liters of CO and 200 DHW) to about 43 degrees Celsius.

In addition, a fireplace with a 24KW water jacket is connected to the container, used occasionally so far.

The floor is powered from the upper part of the buffer through steel pipes (clamping system), the pump is controlled so that it does not pump the coolant cooler than 35 degrees into the floor.

And so, start from the buffer pipe 1 inch, then the thermostatic mixing valve atm341 (protecting against loading too hot medium heated by the fireplace into the floor - the indicator is open to the maximum at 6)) then the pump Wilo Yanos pico 25 / 1-6- (ROW) and then ZZ, then parallel to all three dividers, i.e. one 7-point at the bottom and two 4-point and 6-point on the first floor daw at the top, separated by a tee for 3/4 pipes.

At the moment, the heating is able to maintain the set temperature of about 21 degrees above, while the temperature at the bottom is much higher because the whole is lined with tiles, while the top heats up with more difficulty (most are panels but tiles also in the corridor, bathroom and utility rooms.)

At the moment, the indicators on rotameters oscillate between 0-0.5 and not on all loops. When trying to regulate, i.e. checking the flow on individual beams, after tightening all loops and leaving one (each in turn) on the rotameter, the maximum flow of 2.5-3l / min is displayed. range, but it is known that the pressure in the water supply was greater)

When two manifolds on the third are blocked, the rotameters show the flow in the limit of 1.5.

There is no way I am now able to adjust the flow on the individual loops.

The loops mostly consist of sections of 80 to 100 m, except for 4 shorter ones, between 30-50 meters.

My question is whether the lack of flow is caused by the installation of only one circulation pump for such a large installation, or is it too weak.

What solutions do you recommend?

1.assembly of one more powerful pump - what kind?

2. adding a second pump to supply the attic separately?

3. ???????