I am thinking of installing the panels directly on the rafters.

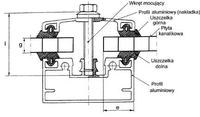

As in the picture:

Grounds:

- easier assembly

- more durable structure - a frame under the panels and cables not exposed to snow, wind and rain

- easier installation - available cables from the bottom of the panels

- lower price - installation on steel profiles mounted to the rafters, without the need to use roof tiles and a roof membrane

Of course, I'm not the first to think about it - whole systems exist. However, I have not encountered any accessories for such assembly of standard panels, maybe I am looking for a wrong one.

Questions:

1. What is the issue of heat dissipation in such an assembly?

2. Are there seals between the edges around regular panels? Or side profiles to connect panels together like tiles like below?

3. Possibly, has anyone applied such a solution?

Thanks in advance for your comments

As in the picture:

Grounds:

- easier assembly

- more durable structure - a frame under the panels and cables not exposed to snow, wind and rain

- easier installation - available cables from the bottom of the panels

- lower price - installation on steel profiles mounted to the rafters, without the need to use roof tiles and a roof membrane

Of course, I'm not the first to think about it - whole systems exist. However, I have not encountered any accessories for such assembly of standard panels, maybe I am looking for a wrong one.

Questions:

1. What is the issue of heat dissipation in such an assembly?

2. Are there seals between the edges around regular panels? Or side profiles to connect panels together like tiles like below?

3. Possibly, has anyone applied such a solution?

Thanks in advance for your comments