mkaminski100 wrote: You can write more about the method of measuring compression that you gave because it is interesting.

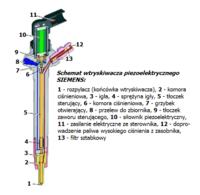

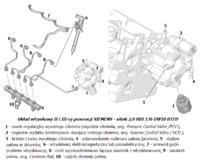

You speak and you have (I reprint my own text from another forum). Despite the fact that the current drive units from the HDi stable and not only work on a different principle than "classic" diesel or VW/Audi unit injectors, a sufficiently good tightness of the combustion chambers is still needed. It is necessary to compress and heat up to 900 degrees C a dose of air enclosed in a cylinder. Only then a dose of fuel is injected using injectors

Common Rail (i.e. under very high pressure of 1800 bar and more) can ignite successfully.

If the combustion chamber is leaky for some reason, then self-ignition is strongly defective, for example due to too low ignition temperature. The engine then starts with difficulty, after repeated ignition several times, emits a lot of smoke from unburnt fuel, and has uneven idle speed. While driving, it also shows bad symptoms of work through some noises, power loss, sometimes jerking and high fuel consumption. All this is happening despite the impeccable condition of the injectors and other starting elements, such as the starter motor and the battery.

Therefore, one of the first checks that is carried out on every diesel engine, when there is a suspicion of damage to the piston rings or any element of the "keyboard", is to perform a compression test. It is also needed due to similar symptoms occurring when injectors fail. It is therefore necessary to determine what is to blame - the cylinder or the injector.

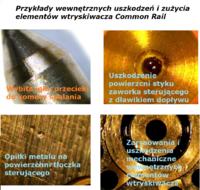

It is wise to check both. However, it does not have to be done automatically when, for example, it is known that the user has just recently replaced a set of injectors. It is unlikely that all four pieces will work badly, unless metal filings have got into them. The latter should be taken care of by each driver himself, checking whether there are no golden metal shavings or so-called gold chips at the bottom of the fuel filter can. "golden flour".

So we naturally conclude that the cylinder compression test should come first. When the "classic" TDI and TD turbo diesels were in use, it was enough to unscrew the injectors or glow plugs from the head and insert the appropriate adapter with a measuring probe in its place, then turn the crankshaft to measure the compression pressure of each cylinder in turn.

For even more accurate measurements, the oil or compressed air method was used, observing the rate of pressure drop and, on this basis, assessing the tightness of the combustion chamber. However, these were "physical" methods, because they required laborious preparations related to the removal of injectors, spark plugs, etc.

Why traditional compression test methods should not be used on your system Common Rail ? When the era of Common Rail turbodiesel came, which probably won't end for a long time, the situation changed dramatically. Injectors and other fuel injection components work under very high pressure, so their threaded connections are extremely sensitive. Violation of the thread and reassembly exposes the entire system to loss of tightness. A thin stream from a leaking high-pressure pipe can easily cut off every finger, including the most important...

In short, any disconnection or opening of the very high pressure injection system, including the injectors, must be avoided at all costs. The same applies to the glow plugs, which, as said, are ceramic and it would be better not to touch them than to touch them even for a compression test.

So there was a problem of "inviolability" of injectors during compression tests and not only, which can be easily solved by using the so-called. indirect, not direct methods of measuring compression pressure. There are basically three methods that are in use, or at least should be:

1. Starter current drop method.

2. Battery current drop method.

3. Measurement method on an existing rotary sensor (usually crankshaft).

For the purposes of this statement, I omit method 3, because you need a normal external diagnoscope with a built-in compression measurement function. Only a few, very expensive diagnostic kits, such as KTS BOSCH, VOLVO, etc., have them. It is rather doubtful that an ordinary workshop could afford such an investment of the price of C4, and maybe even more.

However, any self-respecting service should certainly obtain the necessary equipment to measure the indirect method no. 1 and 2, i.e. the current drop of the starter or battery. Well, two things are necessary for this: an oscilloscope, preferably a 2-channel one, and pliers, current clamps as in the picture below.

The purchase of an oscilloscope with a set of pliers, in my opinion, is profitable for every repair shop, because they can be used to "snap" the entire car electrics, including the signals of all sensors and adjusters. Whereas an ordinary voltmeter does not work because it is too slow.

Method #1 puts a current pliers on the starter cable and, when connected to an oscilloscope, runs the starter and registers a "miniaturized" milliamp current, which in reality draws up to 150 amps. Therefore, pliers are needed.

It should be remembered to prevent the engine from starting by the operation of the injectors, because as you know, it is about checking the cylinders, not the injectors. It is best to remove the plug from one or two injectors or the crankshaft sensor (depending on ease of access).

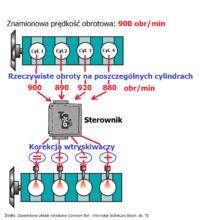

During a few seconds of turning the starter, current "peaks" should appear on the oscilloscope screen as in the picture below. The rest is in the picture description. These peaks indirectly symbolize the compression pressure on each cylinder, converted on the oscilloscope into current signals in the form of a sharp sine wave.

So the peak of each peak should reach as high as possible, which proves good compression, so in this case the sealed cylinder is the most resistant to the starter. Any "unevenness" indicates compression problems, as shown in the second figure.

With an efficient engine, we should read on the oscilloscope the current consumption of at least 35 A and the crankshaft speed of 200 to 300 rpm. A damaged cylinder can be easily recognized by the deviation of these two values. If the starter draws well below 35 amps and the crankshaft speed increases above 300 rpm, there is a loss of cylinder compression, etc.

As a reminder, why do you need a 2-channel oscilloscope. Well, one channel is not enough, as we cannot tell from the graph which cylinder is which. However, with 2-channel, we can connect to the camshaft sensor and thus locate the cylinder number.

Indirect measurement of the current drop of the starter (battery identically) is not as accurate as the oil or compressed air method. However, for our purpose of specifically detecting whether it's a cylinder or an injector, it's precise enough. However, it has a valuable advantage of extremely shortened preparation of the measuring station, without the need to remove anything from the head.

It is worth mentioning by the way that with the help of an oscilloscope, and only an oscilloscope, we can detect damage to itself

pacemaker and

battery . Which, unfortunately, is not possible with a multimeter that only measures a constant drop or rise in a signal, not so complicated and fast. As it is said, it is the strongest weapon against electricity and wherever even "branded" diagnoscopes cannot cope. In my opinion, every reliable diagnostician / mechanic should be armed with it, because cars packed with electronics will not end quickly, quite the opposite.

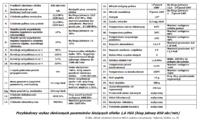

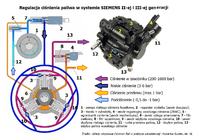

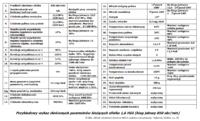

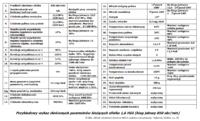

Can the compression drop fault be detected in other ways? It should be noted that it is also possible to initially locate the compression drop fault using an external diagnoscope. Just download the relevant current engine parameters, print and analyze. The differences will be clearly visible in parameters such as injector correction (rows 7-10 in the table of parameters below).

Then, differences in real and theoretical fuel pressures, as well as differences in fuel injection dose, injection start, or injector power supply, will reveal cylinder leaks.

The best and most accurate compression test results are undoubtedly obtained using the sensor found in every engine

TDC and crankshaft speed . In addition, it is an indirect method that does not require the use of current clamps, and therefore does not introduce the own error of the measuring instrument. However, it requires an oscilloscope or an additional oscilloscope function in available external diagnoscopes.

At the same time, the use of the oscilloscope itself requires tips that pierce the insulation of the sensor cables, which is not recommended due to possible signal interference later on.

As you can see, the choice of methodsThe number of non-invasive measurements, not only cylinder compression, is not small and it is worth investing in an oscilloscope, clamps, as well as an appropriate set of connection terminals between cable plugs and pins in the sensor or adjuster. This is to insert the so-called "adapters" that allow you to connect the oscilloscope using "nooks", not terminals that pierce the cable insulation.

Kiss KotBury2