mlodyck wrote: I was also wondering that if it is -20 outside, the pressure on the slat decreases - it is difficult to fire. If I leave the car at such a temperature for several days, after which the temperature rises to -10, the engine starts the first time, the only thing left is the casting symptom for a few seconds. Would it be the fault of the pressure in such a situation? After all, the engine would have to rotate a few times, maybe even a dozen or so, to pump the fuel.

How do you check the fuel pressure in the tank? If, with the help of an external diagnoscope, you can, besides pressure, see many other parameters, including all of them

temperatures during the morning start up. Which should be equal

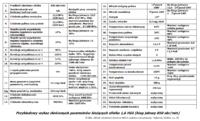

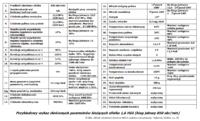

window thermometer (table below, lines 19-21).

One of the most important sensors deciding about quick start is : - Coolant temperature sensor . If it is freezing outside at -20 degrees C., and the coolant temperature sensor is cheating and indicates, for example, +80 degrees, the computer will give a "small" starting fuel dose for the injectors instead of a "high". The engine will not start the first time, only after repeatedly turning the starter, as the computer automatically increases the boot dose.

I emphasize with emphasis what is happening

despite the impeccable condition of the high pressure pump (pwc), control valves, injectors and the entire starting circuit . The computer does not display any error, because the sensor falls into the so-called "measuring goodness", i.e. indicates within acceptable limits.

A characteristic signal that the defect is on the coolant sensor side is

no heating of glow plugs . Everyone gets to them, and in the meantime they will not turn on despite the frost -20 degrees, because the temperature sensor erroneously indicates +80 degrees. Therefore, it is logical that with an allegedly hot engine, the computer will never turn on the heating of candles in life.

The engine will also run unevenly after ignition until the sensor temperature equals the actual liquid temperature. The reason is, as I mentioned, a disproportionately small dose of fuel in relation to current needs.

The principle is simple. If the engine is cold - it needs "a lot" of fuel. If warm - "not enough". The dose of fuel injection is directly controlled by a computer based on the so-called. injection molds, although all components of the injection system work without reservations. One temperature sensor is to blame, which for some reason distorts the electrical signal (from

0.2 down

4.8 V. ) reaching the control computer.

This is a failure of the so-called sensor, often underestimated in diagnostics, because all it seems that when the engine burns badly, some terrible things must happen with the injectors, pwc, etc. Meanwhile, in most cases, the cause may be a very loose cable on the sensor or flooding with some liquid.

The simplest test is to switch off the sensor electrical connector and then try to start the engine. As far as my memory is correct, in 2.0 HDI DW10BTED in Picasso the computer then uses an emergency replacement temperature of -50 degrees C or "last good measurement". See table below, row 19.

Warning! It shows the specifications of the 1.6 HDI engine, so they may vary in detail from your power unit.

If the drive unit lights up immediately from the first time, and when the sensor is turned on, it does not want and works evenly at idle - it indicates a defect of the sensor, more often its cables and contacts.

Usually this happens on the side of the damaged cables and contacts, and not on the sensor itself. Which cannot burn because it is not electrically powered (2-pin sensor) or only 5V (3-pin sensor). It also cannot break down mechanically because there are no moving parts.

You should carefully check whether the sensor is flooded with any liquid, e.g. fuel, oil, water, etc. It may then temporarily distort the resistance, which is a measure of the temperature value for the computer according to Ohm's law. All you have to do is just dry the sensor connector and the problem of starting in cold weather disappears.

I will discuss the remaining parameters if the mentioned coolant sensor turns out to be impeccable. And of course, if you wish me to continue ...

Look at a similar topic

https://www.elektroda.pl/rtvforum/topic3215000.html Kitten KotBury2