Hello,

Pretty standard theme for this model. The machine does not whip milk. I got it from my parents without a milk container (lost) and wanted to fix it so that it works 100%. Until now, he only made coffee and hot water, and when it was given to me even as the milk container was, the milk maker did not froth. Okay, let me get to the point. I ordered a milk container from North.pl (Catalog number: 706-UC-2867) I connected and the milk frothing does not work. I am writing about this container to eliminate it from suspicion. It is new and certainly not clogged.

Symptoms: when I turn on the capuccino mode or frothing milk, the milk is not sucked into the tube, sometimes the level will rise a little, but never suck the milk. Only water vapor and water are flowing from the nozzle. It is also a symptom that instead of sucking milk it blows into the container. This can be seen by the bubbles forming in the container. In a word, the pressure is not enough to draw milk. I read similar topics on the forum, but I don't care about tips like replace all valves and something else. I would like to come to what actually does not work and replace a specific part / parts.

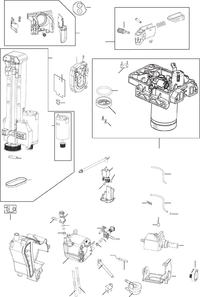

I undressed the express. I attach photos. In the subject https://www.elektroda.pl/rtvforum/topic2959661-30.html

there is a post in which two solenoid valves and a nozzle adapter are indicated as potentially damaged. I exclude the container, because as I mentioned I bought a new one.

I located only one of the solenoids, I don't know where the other is. The adapter has cleaned, as well as the tube that goes out of it to the solenoid valve. I would like to come to the cause of the damage step by step.

My first question is where are the other solenoids and can I clean and check them. I will add that I have the ability to control solenoid valves from an external source (230V AC) after unscrewing and I have access to compressed air, so I could also see if they work properly. My guess is that the solenoid valve in the picture works on the principle that when it is not controlled, it passes water from the top to the left, while in the event of control the left drain is closed, while all the water should go to the right. I might be wrong?

I can be wrong in all these suspicions, so please help me what to clean / check / replace in order for the machine to froth the milk.

However, it seems to me that this is due to the insufficient flow of liquid / vapor through the adapter, which does not create a sufficient vacuum to suck the milk through the hole in the adapter (between the larger and smaller O-rings). And in fact, maybe the solenoid valves do not fully open (damaged) or this adapter is damaged, so this vacuum is not there. Please help.

I attach a video from the test of the aforementioned solenoid valve. If it is not pumped, it feeds the entire air stream to one side (not towards the nozzle adapter), after actuation a loud humming sound is heard, and the flow in the direction in which the nozzle is normally located is minimal. Is it possible that the vacuum is too low to draw milk from the container?

greetings

Pretty standard theme for this model. The machine does not whip milk. I got it from my parents without a milk container (lost) and wanted to fix it so that it works 100%. Until now, he only made coffee and hot water, and when it was given to me even as the milk container was, the milk maker did not froth. Okay, let me get to the point. I ordered a milk container from North.pl (Catalog number: 706-UC-2867) I connected and the milk frothing does not work. I am writing about this container to eliminate it from suspicion. It is new and certainly not clogged.

Symptoms: when I turn on the capuccino mode or frothing milk, the milk is not sucked into the tube, sometimes the level will rise a little, but never suck the milk. Only water vapor and water are flowing from the nozzle. It is also a symptom that instead of sucking milk it blows into the container. This can be seen by the bubbles forming in the container. In a word, the pressure is not enough to draw milk. I read similar topics on the forum, but I don't care about tips like replace all valves and something else. I would like to come to what actually does not work and replace a specific part / parts.

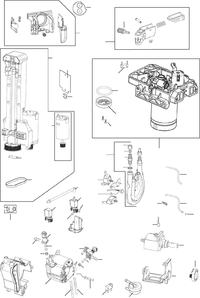

I undressed the express. I attach photos. In the subject https://www.elektroda.pl/rtvforum/topic2959661-30.html

there is a post in which two solenoid valves and a nozzle adapter are indicated as potentially damaged. I exclude the container, because as I mentioned I bought a new one.

I located only one of the solenoids, I don't know where the other is. The adapter has cleaned, as well as the tube that goes out of it to the solenoid valve. I would like to come to the cause of the damage step by step.

My first question is where are the other solenoids and can I clean and check them. I will add that I have the ability to control solenoid valves from an external source (230V AC) after unscrewing and I have access to compressed air, so I could also see if they work properly. My guess is that the solenoid valve in the picture works on the principle that when it is not controlled, it passes water from the top to the left, while in the event of control the left drain is closed, while all the water should go to the right. I might be wrong?

I can be wrong in all these suspicions, so please help me what to clean / check / replace in order for the machine to froth the milk.

However, it seems to me that this is due to the insufficient flow of liquid / vapor through the adapter, which does not create a sufficient vacuum to suck the milk through the hole in the adapter (between the larger and smaller O-rings). And in fact, maybe the solenoid valves do not fully open (damaged) or this adapter is damaged, so this vacuum is not there. Please help.

I attach a video from the test of the aforementioned solenoid valve. If it is not pumped, it feeds the entire air stream to one side (not towards the nozzle adapter), after actuation a loud humming sound is heard, and the flow in the direction in which the nozzle is normally located is minimal. Is it possible that the vacuum is too low to draw milk from the container?

greetings