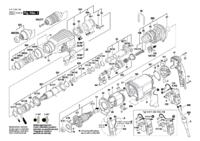

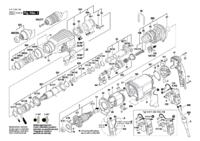

Hello, I got a damaged Bosch 2-26 DFR rotary hammer. After replacing the brushes she started, but with virtually no stroke. I replaced the following: 321/59, 321/58, 321/60, 26/56, bearing on the 3/14 rotor, plate 48 and bearing underneath.

Everything folded and greased but no impact. What else could I miss?

Everything folded and greased but no impact. What else could I miss?