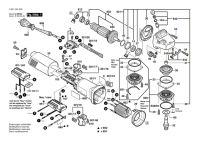

kołodziej25 wrote: I have a problem, namely I can not halve this grinder and I do not know what I am doing wrong, and I want to replace all the bearings because they have play.

Maybe someone will advise because I have no idea anymore. On YouTube, the guy after unscrewing easily pulled the rotor at this stage, and for me it is not possible.

If you cannot pull out the rotor, then, as colleagues have said before, you have an overheated stator.

I assume you have at least a vice.

In it, grab the grinder firmly by the aluminum head so that you can hit the plastic body with a hammer. So you have it in a vice. You turn the body slightly so that you have a pounding edge and hit it with a hammer through e.g. a piece of wood.

You have to see if the wires get tense when knocking out. If the stator is strongly welded, you will have to disconnect all cables from the electronics and brush holders so that the rotor comes out of the body together with the stator.

Of course, the nut on the rotor is unscrewed with an open-end wrench, not an impact wrench.

If you do not damage the magnet, it does not need to be replaced after each disassembly. It is removed together with the placenta.

The bearing in the bearing flange is non-replaceable (sealed in plastic). It is completely replaced. At least a hand press is required to pull the wheel off.

Generally, without the press, don't do it.