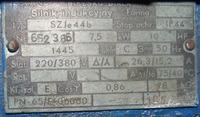

Hello, I have a splitter like in the picture. 7.5 kw engine, 1440 revolutions, drill fi 80, drive for belts 17 two pieces length 1050, belt pulley on the engine external dimension 80 and shaft on the shaft fi 170. The problem is that the drill comes into a tree and blocks . The belts slide on the engine. When I pull the straps, the drill comes in and stands again. I will split the tree on the pine tree. Pr I brought a tree called elm and that's how it is that the splitter is becoming. Even when I take a tree with my sides it is also the same. I thought I could put on longer straps for example 1300. But will it help? someone has an idea. The engine was checked by an electrician and is ok.