Hello!

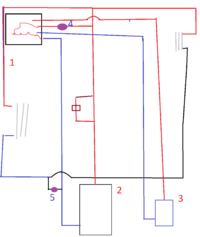

I have to replace the CO furnace and by the way I would like to redo my installation . My installation consists of a central heating boiler and a small boiler that heats the water in the boiler, it has no coil, i.e. the water that flows from the hot tap in the tap also comes from the small stove. The stove is tiny and heats up my water very quickly, I don't want to remove it until it is leaking. Of course, the CO furnace has a coil. My problem is that when I heat the water with a small stove in the summer, sometimes the heaters on the floor get warm. I would like someone to mark me on the diagram where I can install valves to avoid heat loss, and where to install valves to be able to heat only the boiler without radiators with the CO furnace.

. My installation consists of a central heating boiler and a small boiler that heats the water in the boiler, it has no coil, i.e. the water that flows from the hot tap in the tap also comes from the small stove. The stove is tiny and heats up my water very quickly, I don't want to remove it until it is leaking. Of course, the CO furnace has a coil. My problem is that when I heat the water with a small stove in the summer, sometimes the heaters on the floor get warm. I would like someone to mark me on the diagram where I can install valves to avoid heat loss, and where to install valves to be able to heat only the boiler without radiators with the CO furnace.

1. BOILER WITH 4 CONNECTIONS 2 TO COIL 2 DIRECTLY INTO THE INTERIOR.

2. BOILER CO

3. THE SMALL HOT WATER STOVE

The four outputs in the corners of the diagram are the installation of radiators.

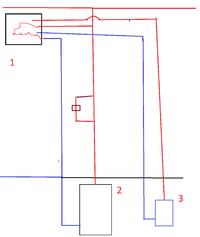

I have to replace the CO furnace and by the way I would like to redo my installation

. My installation consists of a central heating boiler and a small boiler that heats the water in the boiler, it has no coil, i.e. the water that flows from the hot tap in the tap also comes from the small stove. The stove is tiny and heats up my water very quickly, I don't want to remove it until it is leaking. Of course, the CO furnace has a coil. My problem is that when I heat the water with a small stove in the summer, sometimes the heaters on the floor get warm. I would like someone to mark me on the diagram where I can install valves to avoid heat loss, and where to install valves to be able to heat only the boiler without radiators with the CO furnace.

. My installation consists of a central heating boiler and a small boiler that heats the water in the boiler, it has no coil, i.e. the water that flows from the hot tap in the tap also comes from the small stove. The stove is tiny and heats up my water very quickly, I don't want to remove it until it is leaking. Of course, the CO furnace has a coil. My problem is that when I heat the water with a small stove in the summer, sometimes the heaters on the floor get warm. I would like someone to mark me on the diagram where I can install valves to avoid heat loss, and where to install valves to be able to heat only the boiler without radiators with the CO furnace. 1. BOILER WITH 4 CONNECTIONS 2 TO COIL 2 DIRECTLY INTO THE INTERIOR.

2. BOILER CO

3. THE SMALL HOT WATER STOVE

The four outputs in the corners of the diagram are the installation of radiators.