Hello;

I am a few days before installing a new boiler in an old house. Installation is large diameter from the 70's steel, two-story house.

The new boiler also uses solid fuel.

The situation is complicated by the desire to install a 4d valve with an actuator.

The problem is that there is no extra pipe to the expansion vessel, but it looks like the vessel is connected somewhere upstairs to the heater return and only the overflow pipe returns from there.

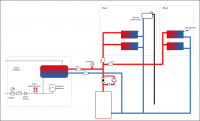

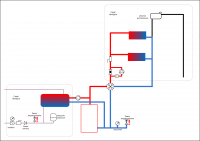

The installation (of course, omitting the 4d valve and the common CH and DHW pump) now looks as follows:

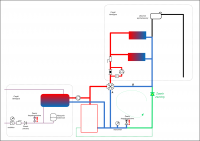

Now the situation with the 4d valve: summer mode (or failure of the valve or control, or even the DHW priority) and the 4d valve cuts off the radiator circuit and the system becomes closed, ready to explode.

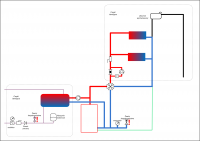

How to prevent it?

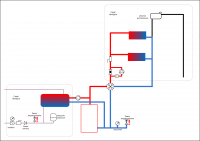

It is not possible to modify by adding a pipe to the vessel.

I am a few days before installing a new boiler in an old house. Installation is large diameter from the 70's steel, two-story house.

The new boiler also uses solid fuel.

The situation is complicated by the desire to install a 4d valve with an actuator.

The problem is that there is no extra pipe to the expansion vessel, but it looks like the vessel is connected somewhere upstairs to the heater return and only the overflow pipe returns from there.

The installation (of course, omitting the 4d valve and the common CH and DHW pump) now looks as follows:

Now the situation with the 4d valve: summer mode (or failure of the valve or control, or even the DHW priority) and the 4d valve cuts off the radiator circuit and the system becomes closed, ready to explode.

How to prevent it?

It is not possible to modify by adding a pipe to the vessel.