Hello

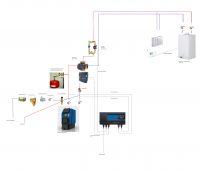

I have planned modernization of the boiler room and, therefore, I ask interested parties to correct my scheme

I currently have 2 furnaces, of which the installation works in a closed system on a gas furnace, I would like to add a coal stove to the installation.

I would like the coal furnace to be responsible only for central heating, when heating with a coal boiler I will turn off the valves in the gas furnace and turn off the central heating operation, it will remain only as water heating

my questions:

1.Currently, the pipes for radiators are pex 25 as a riser, for modernization I will use copper - for CU 28 boiler circuit, for circulation after 4d Cu 22 valve - will the diameters be ok? At home 5 radiators in the rooms, 2 ladders in the bathrooms, floors on 3 rtl valves (2 bathrooms + kitchen) with a total area of 23m2, the whole house 120 m2

2. Placing the safety group on power supply? Does the safety group have to be at the highest point of the boiler room?

3. How to choose an expansion vessel for safety group? From what I know is 8% of the total water in the system. Or should the container be on the return to the valve with a vent on the supply?

4.Positioning the pump on the flow? maybe it would be better if it were on return then it would work both on the boiler circuit (smaller) as after the 4d valve, if it is after the 4d valve then the boiler circuit remains gravitational

5. Will the differential valve in the event of a power failure in such a system fulfill its role if it is behind a 4d valve?

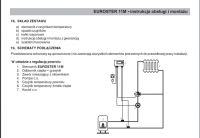

6. I would like to use the Euroster E11M controller to control a coal stove - is it connected correctly?

7. Is the cooling valve properly connected?

Thank you in advance for your time

I have planned modernization of the boiler room and, therefore, I ask interested parties to correct my scheme

I currently have 2 furnaces, of which the installation works in a closed system on a gas furnace, I would like to add a coal stove to the installation.

I would like the coal furnace to be responsible only for central heating, when heating with a coal boiler I will turn off the valves in the gas furnace and turn off the central heating operation, it will remain only as water heating

my questions:

1.Currently, the pipes for radiators are pex 25 as a riser, for modernization I will use copper - for CU 28 boiler circuit, for circulation after 4d Cu 22 valve - will the diameters be ok? At home 5 radiators in the rooms, 2 ladders in the bathrooms, floors on 3 rtl valves (2 bathrooms + kitchen) with a total area of 23m2, the whole house 120 m2

2. Placing the safety group on power supply? Does the safety group have to be at the highest point of the boiler room?

3. How to choose an expansion vessel for safety group? From what I know is 8% of the total water in the system. Or should the container be on the return to the valve with a vent on the supply?

4.Positioning the pump on the flow? maybe it would be better if it were on return then it would work both on the boiler circuit (smaller) as after the 4d valve, if it is after the 4d valve then the boiler circuit remains gravitational

5. Will the differential valve in the event of a power failure in such a system fulfill its role if it is behind a 4d valve?

6. I would like to use the Euroster E11M controller to control a coal stove - is it connected correctly?

7. Is the cooling valve properly connected?

Thank you in advance for your time

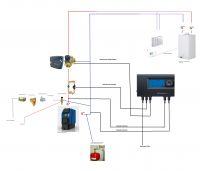

. Returning to the subject of the scheme, as for me, a great overflow vessel I was left with, I thought it would no longer be useful. Installation in such a system would be the simplest and cheapest for me. In this case, it shows its diagram, as I wrote after leaving the furnace, pipes reduced to CU 28. In the installation there will be about 150 l counting both stoves and water in the pipes and radiators, so the overflow expansion vessel 15l is probably just right. 19kw gas furnace, coal 8-10 kw, so 20 KW heat exchanger will be good? And the assumption of burning in a coal furnace is that the shut-off valves from the gas furnace must be open, the furnace has a built-in diaphragm vessel and a safety valve. Last request to check the installation pattern

. Returning to the subject of the scheme, as for me, a great overflow vessel I was left with, I thought it would no longer be useful. Installation in such a system would be the simplest and cheapest for me. In this case, it shows its diagram, as I wrote after leaving the furnace, pipes reduced to CU 28. In the installation there will be about 150 l counting both stoves and water in the pipes and radiators, so the overflow expansion vessel 15l is probably just right. 19kw gas furnace, coal 8-10 kw, so 20 KW heat exchanger will be good? And the assumption of burning in a coal furnace is that the shut-off valves from the gas furnace must be open, the furnace has a built-in diaphragm vessel and a safety valve. Last request to check the installation pattern