Hello, I decided to rewind the winding of the damaged rotor from my slash, I have a supply of winding wire and access to the balancing machine, so it should work.

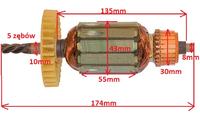

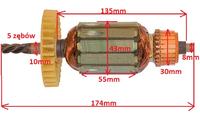

The rotor has 12 nurseries, and the commutator 24, dimensioned in the photo below (maybe someone has such a rotor for sale or knows where to get it?) The engine theoretically has a power of 1500 W:

The problem is that I have trouble recreating the winding, as if it were wound with two wires at the same time alternately, every few turns - maybe someone with this type of arrangement met?

I was able to play so much, sorry for the crooked drawing

The rotor has 12 nurseries, and the commutator 24, dimensioned in the photo below (maybe someone has such a rotor for sale or knows where to get it?) The engine theoretically has a power of 1500 W:

The problem is that I have trouble recreating the winding, as if it were wound with two wires at the same time alternately, every few turns - maybe someone with this type of arrangement met?

I was able to play so much, sorry for the crooked drawing