Hello and help, please.

I have a single-phase ~ 230V / 50Hz motor with 2.2kW 2820 rpm burned, current according to the rating plate: 15.3A. The motor has two 45 micronF capacitors installed.

The start winding and work winding are burnt. After disassembly for rewinding, it turned out that there is also a thermostat connected to the winding but not connected to the control box. I decided to improve this protection at the stage of winding replacement by performing control in the breaker box.

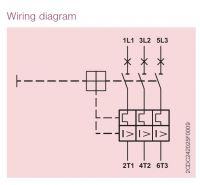

The ABB MS1 16-20 manual circuit breaker is located in this motor breaker box. It looks like the picture below:

How to attach the above thermal protection to this switch? Should the auxiliary contacts HK1-20 be used for this? (picture)

Is this the right accessory for this purpose? I do not want to change the switch because it fits well in the housing and there is still space on the rail for such contacts.

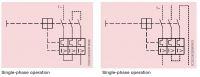

The circuit breaker has these two connection diagrams assigned to a single-phase motor:

Thank you in advance for your interest and kind response.

I have a single-phase ~ 230V / 50Hz motor with 2.2kW 2820 rpm burned, current according to the rating plate: 15.3A. The motor has two 45 micronF capacitors installed.

The start winding and work winding are burnt. After disassembly for rewinding, it turned out that there is also a thermostat connected to the winding but not connected to the control box. I decided to improve this protection at the stage of winding replacement by performing control in the breaker box.

The ABB MS1 16-20 manual circuit breaker is located in this motor breaker box. It looks like the picture below:

How to attach the above thermal protection to this switch? Should the auxiliary contacts HK1-20 be used for this? (picture)

Is this the right accessory for this purpose? I do not want to change the switch because it fits well in the housing and there is still space on the rail for such contacts.

The circuit breaker has these two connection diagrams assigned to a single-phase motor:

Thank you in advance for your interest and kind response.