Hello

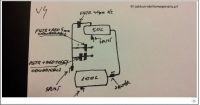

I want to build a pneumatic installation in a garage based on a PEX system.

The compressor I have is MAKTEK SKY300W (new, more powerful model). Initially I was thinking about 1/2 inch installation and here's the question. Is 1/2 enough? The compressor actually blows over 800 liters / min and I do not know if this installation could handle it. Initially, the assumption is 1/2 inch for economic reasons. It should be taken into account that the couplings can be 8mm inside.

I am asking for advice from smarter heads, maybe there is someone who could calculate what and how?

I want to build a pneumatic installation in a garage based on a PEX system.

The compressor I have is MAKTEK SKY300W (new, more powerful model). Initially I was thinking about 1/2 inch installation and here's the question. Is 1/2 enough? The compressor actually blows over 800 liters / min and I do not know if this installation could handle it. Initially, the assumption is 1/2 inch for economic reasons. It should be taken into account that the couplings can be 8mm inside.

I am asking for advice from smarter heads, maybe there is someone who could calculate what and how?